High tacky subli-paper

High viscosity sublimation paper is the first genetically modified adhesive paper from Keditec. Due to the optimization of approximately 8-9 grams of adhesive coating, there is no movement between the paper and fabric during sublimation transfer, which will eliminate possible ghosting. Our high viscosity sublimation paper ensures printing and transfer effects, guarantees the clarity and vividness of patterns, and more importantly, ensures stable printing quality for long-term printing, without leaving sticky residues on textiles. It is particularly suitable for high demand printing work on elastic fabrics such as sportswear.

Advantages

-

No ghosting and good drying time.

-

It can minimize textile shrinkage to the greatest extent possible.

-

Enhanced viscosity effect, suitable for various spandex textiles.

-

The adhesion between the heat sublimation paper and the fabric is enhanced after transfer printing.

-

Clear text and fine lines, as there is no movement between paper and fabric.

Feature

- Suitable for Lycra, polyester polyester, and spandex fabrics.

- Specially designed for elastic textiles.

- The level of stickiness depends on the fabric used.

- Testing is required before use.

Testing Condition

Ink-load: 400%

Max Transfer Temperature: 200-230℃

Transfer Time: 20-30 seconds

About Storage

In order to protect unused sublimation paper, it is recommended to store it in its original packaging, in the poly bag at 68°F -82°F( 20°C -28°C) and 40-60% RH.

About Printing

The image side is wound to the outside of the paper. Printing is performed in a ″mirror″ image. Allow the printing ink to dry before transferring.

Specifications

Weight

- 70GSM

- 80GSM

- 90GSM

- 100GSM

- 105GSM

Roll widht

- 16.5″/ 42cm

- 24″/ 61cm

- 36″/ 91.4cm

- 44″/ 118.cm

- 54″/ 132cm

- 63″/ 160cm

- 64″/ 162cm

- 72″/190cm

- 126″/320cm

Roll length

- 100m / 328ft

Temperature

- 210℃

Time

- 30S

Cleaning Times

- Unlimited times

Pressure

- High Pressure

Provide customized services and sample, if necessary, please contact us.

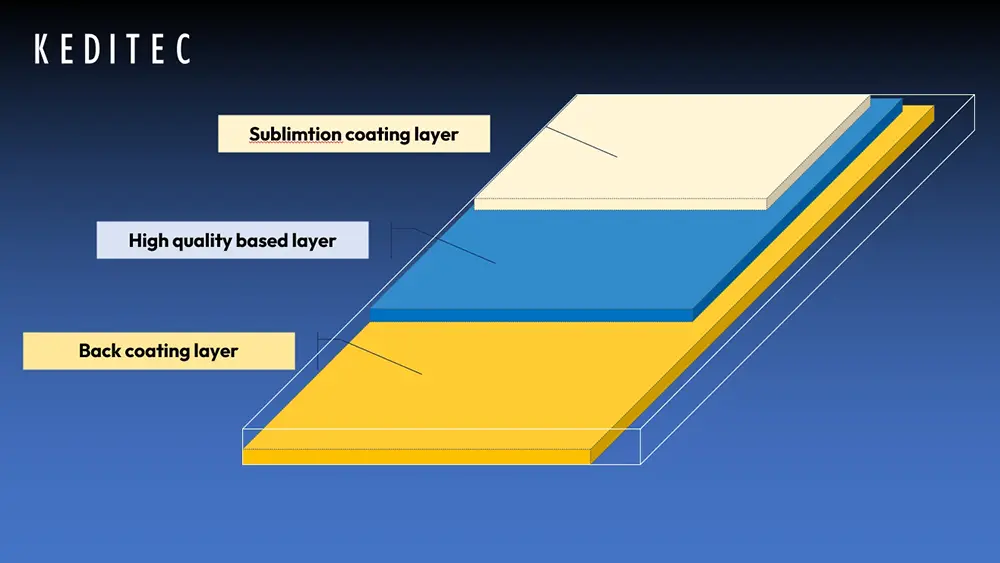

Physical structure

Sublimation paper is crucial in sublimation printing. Its structure consists of a base layer, a coating layer, and a protective layer. The base layer is made of high-quality paper material, providing support and ensuring strength for transmission. The coating layer is the core, composed of special polymer materials. It has ink affinity and thermal stability, can adsorb dye molecules and transfer by sublimation at high temperatures, and determines the color, clarity, and durability of the image. The protective layer can be waterproof, scratch-resistant, and UV-resistant, protecting the image and prolonging its lifespan. It is usually a transparent film or special coating. Its structure ensures high-quality printing, improves transfer efficiency and success rate, and adapts to different scenarios.

Steps to use

Step 1 : Create the design, design it on your computer, and mirror it before printing.

Step 2 : Sublimation printing, only use an inkjet printer with sublimation ink to print on the white surface of the sublimation paper.

Step 3 : Wait for the image to dry and preheat the fabric to remove wrinkles and moisture.

Step 4 : Heat transfer, preheat the hot press to the temperature you set, adjust the pressing time appropriately, make the printed image face the fabric and start the pressing process.

Step 5 : Remove the hot press and tear off the transfer paper

Supply Chain

Contact us