AW art watercolor subli-paper

AW paper is a special kind of paper specifically designed for sublimation printing. Sublimation printing is an advanced printing technology that converts solid ink into gaseous state by heating and makes it penetrate into the printing medium, thereby achieving colorful, durable and high-resolution printing effects.

Feature

- Good ink absorption: It can quickly absorb heat-sublimated ink to ensure clear patterns and bright colors. During the transfer process, the ink can be fully sublimated and transferred to the substrate, resulting in high-quality image effects.

- High transfer rate: It allows the thermally sublimated ink to be efficiently transferred from the paper to the surface of the target object at high temperature, reducing ink residue, improving transfer efficiency and quality, and saving ink costs.

- The paper strength is moderate: it not only has a certain degree of toughness, but also is not easy to tear during printing and transfer, and it can ensure that the paper will not be overly deformed or damaged under the high temperature and high pressure of the thermal transfer equipment, ensuring the smooth progress of the transfer process.

Testing Condition

Ink-load: 400%

Max Transfer Temperature: 200-230℃

Transfer Time: 20-30 seconds

About Storage

In order to protect unused sublimation paper, it is recommended to store it in its original packaging, in the poly bag at 68°F -82°F( 20°C -28°C) and 40-60% RH.

About Printing

The image side is wound to the outside of the paper. Printing is performed in a ″mirror″ image. Allow the printing ink to dry before transferring.

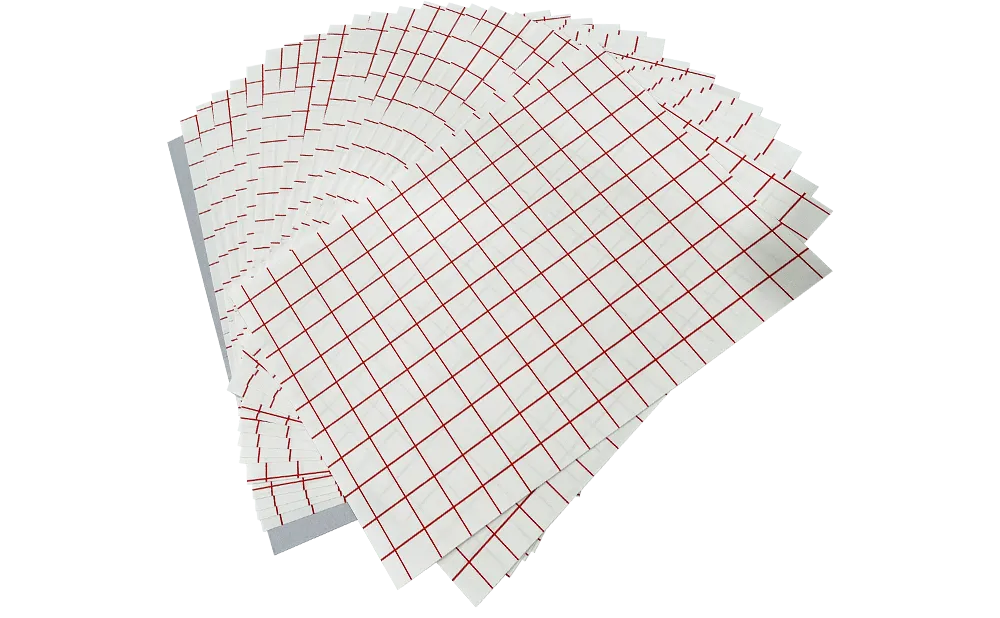

Specifications

Weight

- 105 GSM

- 120 GSM

Size

- A3

- A4

Storage environment

- Avoid direct sunlight

- Indoor storage

- Temperature 10-30 ℃

Provide customized services and sample, if necessary, please contact us.

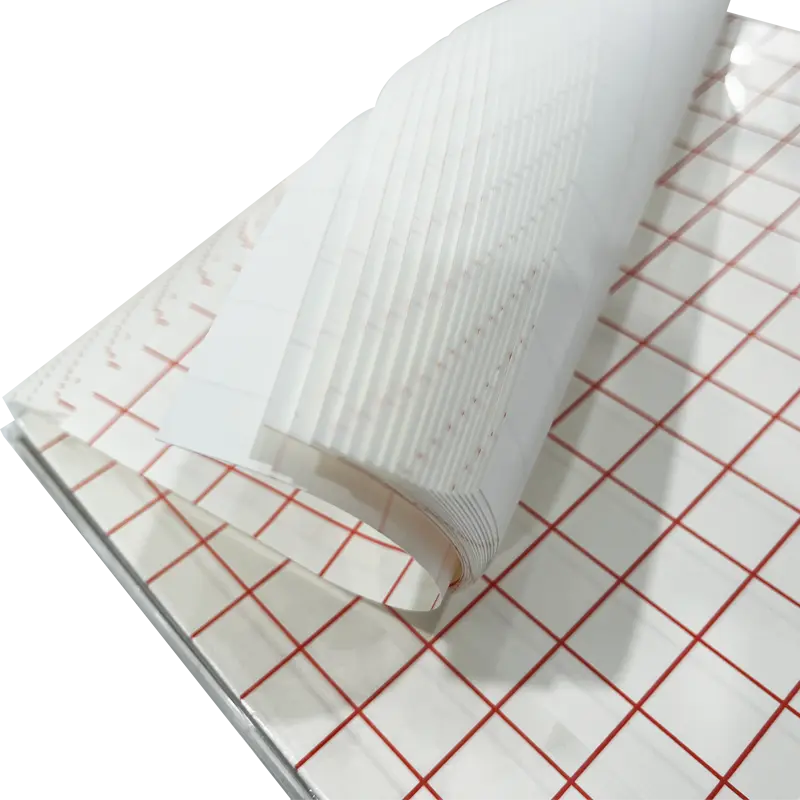

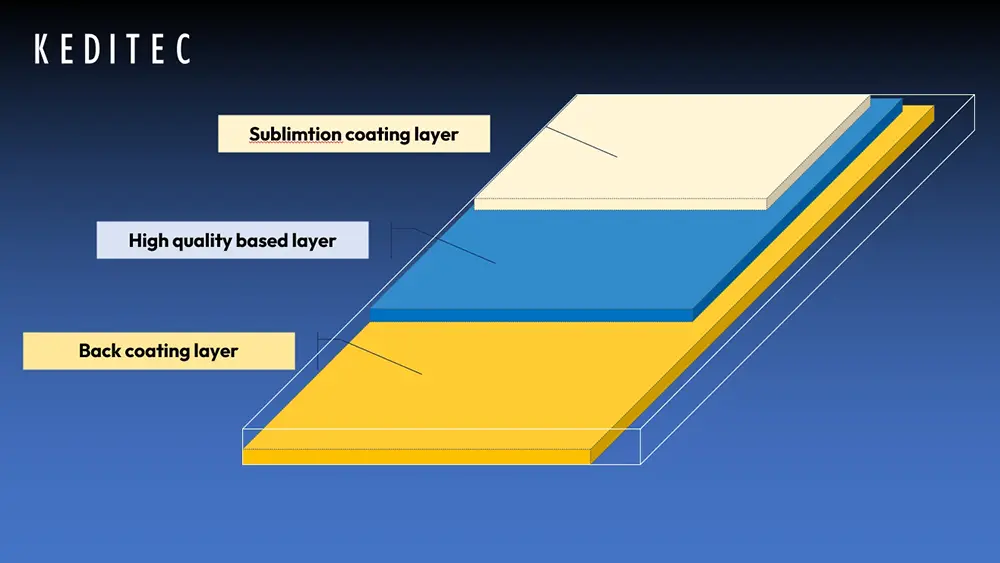

Physical structure

Sublimation paper is crucial in sublimation printing. Its structure consists of a base layer, a coating layer, and a protective layer. The base layer is made of high-quality paper material, providing support and ensuring strength for transmission. The coating layer is the core, composed of special polymer materials. It has ink affinity and thermal stability, can adsorb dye molecules and transfer by sublimation at high temperatures, and determines the color, clarity, and durability of the image. The protective layer can be waterproof, scratch-resistant, and UV-resistant, protecting the image and prolonging its lifespan. It is usually a transparent film or special coating. Its structure ensures high-quality printing, improves transfer efficiency and success rate, and adapts to different scenarios.

Steps to use

Step 1 : Create the design, design it on your computer, and mirror it before printing.

Step 2 : Sublimation printing, only use an inkjet printer with sublimation ink to print on the white surface of the sublimation paper.

Step 3 : Wait for the image to dry and preheat the fabric to remove wrinkles and moisture.

Step 4 : Heat transfer, preheat the hot press to the temperature you set, adjust the pressing time appropriately, make the printed image face the fabric and start the pressing process.

Step 5 : Remove the hot press and tear off the transfer paper

Supply Chain

Contact us