A3 / A4 super sheet subli-paper

Keditec A3/A4 models of thermal sublimation transfer paper have the characteristics of high transfer rate, bright colors and realistic images. A3/A4 ultra-thin thermal sublimation paper also performs well in terms of product performance. Its paper has high flatness, ensuring that there will be no wrinkles during printing and transfer, thus guaranteeing the perfect presentation of the transfer effect. This thermal sublimation paper can quickly absorb the thermal sublimation ink, so that the ink dries quickly on the paper, avoiding the smudging and diffusion of the ink. At the same time, it has a good degree of color reproduction, which can truly transfer the color of the image to the substrate without fading or cracking, making the transferred item durable.

Feature

- Ultra-thin characteristics: The paper thickness is thinner, which can reduce costs on the one hand, and on the other hand, it can better fit with the substrate during the heat transfer process, making the heat transfer more uniform, which helps to improve the transfer effect and efficiency.

- Good ink absorption: It can quickly absorb heat-sublimated ink, prevent ink smudging and diffusion, ensure the clarity and accuracy of the print pattern, and present bright and realistic colors.

- Good air permeability: After thermal transfer, the paper where the pattern is located can be better breathable, so that the pattern transferred to textiles and other substrates has good air permeability and is more comfortable to wear.

- Flexibility: Paper has a certain degree of flexibility, making it difficult to break or damage during printing or transfer, making it easy to operate and use

Testing Condition

Ink-load: 400%

Max Transfer Temperature: 200-230℃

Transfer Time: 20-30 seconds

About Storage

In order to protect unused sublimation paper, it is recommended to store it in its original packaging, in the poly bag at 68°F -82°F( 20°C -28°C) and 40-60% RH.

About Printing

The image side is wound to the outside of the paper. Printing is performed in a ″mirror″ image. Allow the printing ink to dry before transferring.

Specifications

Weight

- 13Kg / 1 carton

Quantity

- A3: 1000 sheets in one carton.

- A3: 1000 sheets in one carton.

Size

- A3 : 29.7cm×42cm

- A4 : 21cm×29.7cm

- 46*32*14CM / Carton

Temperature

- 210℃

Time

- 30S

Cleaning Times

- Unlimited times

Pressure

- High Pressure

Provide customized services and sample, if necessary, please contact us.

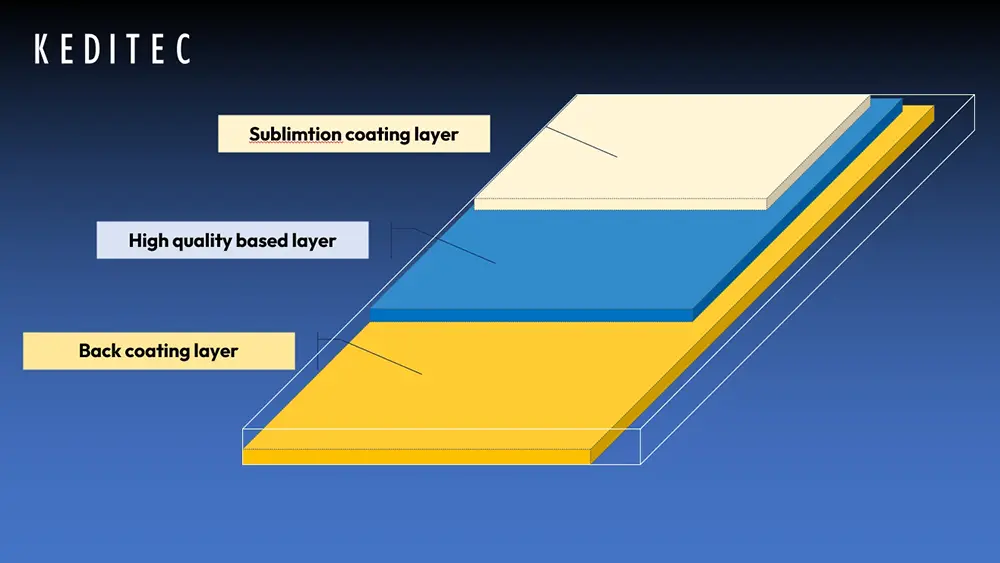

Physical structure

Sublimation paper is crucial in sublimation printing. Its structure consists of a base layer, a coating layer, and a protective layer. The base layer is made of high-quality paper material, providing support and ensuring strength for transmission. The coating layer is the core, composed of special polymer materials. It has ink affinity and thermal stability, can adsorb dye molecules and transfer by sublimation at high temperatures, and determines the color, clarity, and durability of the image. The protective layer can be waterproof, scratch-resistant, and UV-resistant, protecting the image and prolonging its lifespan. It is usually a transparent film or special coating. Its structure ensures high-quality printing, improves transfer efficiency and success rate, and adapts to different scenarios.

Steps to use

Step 1 : Create the design, design it on your computer, and mirror it before printing.

Step 2 : Sublimation printing, only use an inkjet printer with sublimation ink to print on the white surface of the sublimation paper.

Step 3 : Wait for the image to dry and preheat the fabric to remove wrinkles and moisture.

Step 4 : Heat transfer, preheat the hot press to the temperature you set, adjust the pressing time appropriately, make the printed image face the fabric and start the pressing process.

Step 5 : Remove the hot press and tear off the transfer paper

Supply Chain

Contact us