I. Core Root Cause of DTF Printer Shaking: Design Defects in Base and Counterweight

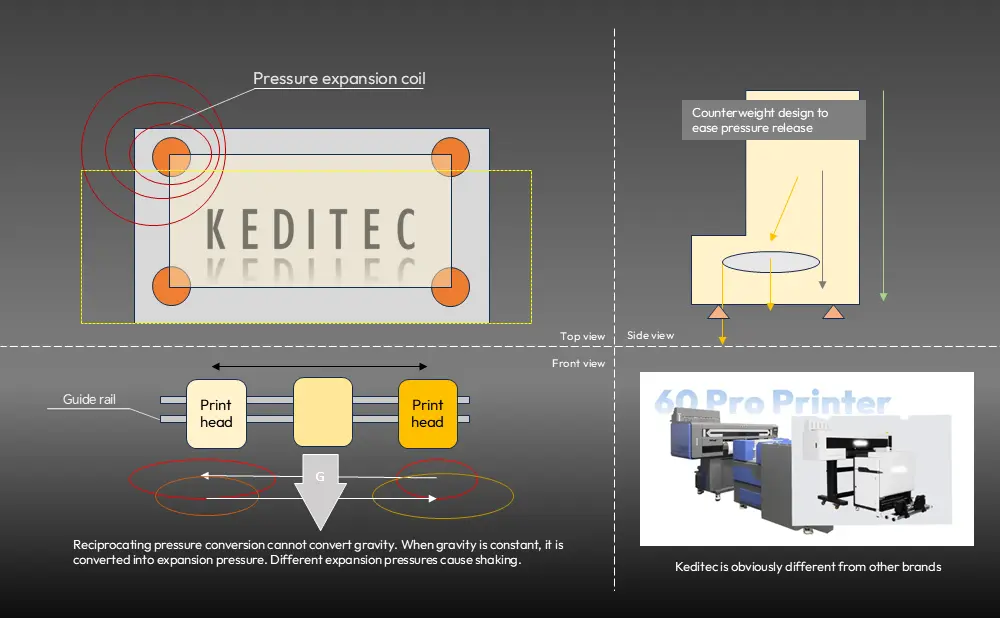

During high-speed printing with a DTF printer, shaking is a common hazard affecting printing accuracy. It is essentially an external manifestation of dynamic balance failure in the printer’s mechanical system, with core causes concentrated in two design aspects: the base and the counterweight.

From the perspective of base design, insufficient stability is a common issue in most low-end DTF printers. To cut costs, some manufacturers adopt a base structure formed by bending thin steel plates without setting reinforcing ribs or shock-absorbing chambers, resulting in insufficient base rigidity. When the printer’s print head moves back and forth at a speed of 0.5-1.2 meters per second, the generated inertial force causes the base to resonate. Especially when the printer’s printing width exceeds 60cm, the resonance frequency can reach 5-8Hz, which forms coupled vibration with the desktop or ground and further amplifies the shaking amplitude. In addition, if the contact area between the printer base and the ground is unreasonably designed, a single-point support or small-area contact structure cannot effectively distribute the machine weight, which will intensify the transmission of shaking and eventually lead to positioning deviation of the PET film printed by the DTF printer.

The lack or imbalance of counterweight design is one of the key differences between mid-to-high-end and low-end DTF printers. The print head of a DTF printer (including components such as the nozzle and ink stack) usually weighs 3-8kg, and the inertial torque generated during high-speed movement needs to be offset by the counterweight system. If the DTF printer is not equipped with a counterweight device, or the counterweight block is insufficient in weight or offset in position, the center of gravity of the machine will continuously shift with the movement of the print head, resulting in periodic shaking. Experimental data shows that when the counterweight mass of the DTF printer is less than 1.5 times the mass of the print head assembly, the shaking amplitude will exceed 0.5mm, directly causing blurred printed patterns or misregistration, and affecting the production efficiency and finished product quality of the DTF printer.

II. Cost Game Between DTF Printer Frame and Counterweight: Price and Advantage Comparison of Different Designs

The selection of frame steel pipe welding process and counterweight plate design directly determines the cost and stability of the DTF printer. Currently, DTF printers on the market are mainly divided into three cost-effective solutions to meet the needs of different users:

(I) Economic DTF Printer: Thin-Walled Steel Pipe Welding + No Counterweight Plate

This type of DTF printer adopts a frame welded with ordinary welded pipes of 1.2-1.5mm thickness and has no counterweight design. It is mainly aimed at individual entrepreneurs or small-batch printing needs. Its advantage is that it is suitable for small desktop DTF printers and can meet the basic stability requirements for printing with a width of less than 30cm.

(II) Mid-Range DTF Printer: Thick-Walled Steel Pipe Welding + Adjustable Counterweight Plate

Mid-range DTF printers use a frame welded with seamless steel pipes of 2.0-3.0mm thickness and adopt a combined counterweight plate fixed by bolts (counterweight blocks can be added or reduced, with a total weight of 5-8kg). They are the mainstream choice for small and medium-sized studios. To ensure the stability of the DTF printer, the frame processing needs to undergo flaw detection, and the cost proportion increases to 15%-20%. The core advantage of this type of DTF printer is the balance between stability and flexibility. By adjusting the number of counterweight blocks, it can be adapted to print heads of different weights. The rigidity of the welded frame is sufficient to support high-speed printing with a width of 40cm, which can meet the mass production needs of most DTF printer users.

(III) High-End DTF Printer: Integral Square Steel Welding + Integrated Counterweight Chassis

High-end DTF printers adopt an integral welded frame made of 40×60mm square steel and are matched with a cast iron counterweight chassis integrated with the base (weighing 15-30kg, including a shock-absorbing chamber design). They are mainly used in industrial scenarios such as clothing factories. The frame processing accuracy of the DTF printer is required to reach ±0.5mm, and the cost proportion is as high as 25%-35%. The advantage of this type of DTF printer lies in the realization of coordinated shock absorption between the mechanical structure and the counterweight system. Through the center of gravity optimization of the counterweight chassis and the elastic buffer structure inside the shock-absorbing chamber, the shaking amplitude of the DTF printer can be controlled within 0.1mm, which fully meets the industrial production needs of printing with a width of 120cm and is the first choice for high-demand DTF printer users.

III. Core of Scientific Counterweight for DTF Printers: Mainstream Calculation Methods and Application Scenarios

Reasonable counterweight calculation is the key to solving the shaking problem of DTF printers. Currently, the industry mainly adopts three calculation methods for different levels of DTF printers:

(I) Static Balance Method: Suitable for Small DTF Printers

This method focuses on the static center of gravity balance of the DTF printer. The calculation formula is: Counterweight Mass (m) = Print Head Mass (m1) × Maximum Print Head Movement Distance (L1) ÷ Distance from Counterweight Center of Gravity to Rotation Axis (L2). For example, when the print head mass of the DTF printer is 5kg, the maximum movement distance is 60cm, and the distance from the counterweight center of gravity to the rotation axis is 30cm, the required counterweight mass is 5×60÷30=10kg. This method is simple to calculate and does not require complex parameters. It is suitable for small bracket-free DTF printers with a printing speed lower than 0.5m/s, which can basically offset the shaking caused by static center of gravity deviation and meet the basic stability needs of individual users for DTF printers.

(II) Inertial Torque Balance Method: Suitable for Desktop DTF Printers

For desktop DTF printers with medium and high-speed printing, the inertial torque balance formula needs to be introduced: Counterweight Moment of Inertia (Jp) = Print Head Moment of Inertia (Jm) × Safety Factor (k). Among them, the moment of inertia J=mr² (m is mass, r is the radius of the center of gravity), and the safety factor k is usually 1.2-1.5. Taking a desktop DTF printer with a width of 40cm as an example, the moment of inertia of the print head assembly is 0.8kg·m². Calculated by k=1.4, the counterweight moment of inertia needs to reach 1.12kg·m². If a counterweight block with a radius of 0.2m is selected, its mass needs to reach 28kg. This method can effectively balance the inertial torque generated by the high-speed movement of the DTF printer’s print head. It is the standard calculation method for desktop DTF printers with external brackets, ensuring that the DTF printer operates stably at a printing speed of 0.5-0.8m/s.

(III) Resonance Suppression Method: Suitable for Production-Grade DTF Printers

Based on the inertial torque balance, this method introduces vibration frequency parameters and is specially designed for production-grade DTF printers. The calculation formula is: Counterweight Mass (m) = Total Equipment Mass (M) × Square of Resonance Frequency (f²) × Shock Absorption Coefficient (c). The shock absorption coefficient c is 0.3-0.8 depending on the shock absorption structure of the DTF printer base. A production-grade DTF printer with a width of 120cm has a total mass of about 300kg. If the detected resonance frequency is 6Hz and a spring shock absorption structure is adopted (c=0.5), in practical application, the total counterweight mass of the DTF printer will be controlled at 30%-50% of the equipment’s own mass through segmented counterweight and elastic buffer design. Combined with the opposite counterweight block design inside the shock-absorbing chamber, internal offset of the vibration force is realized, ensuring that the DTF printer remains stable during high-speed printing at 1.0-1.2m/s.

IV. Hierarchical Solutions for DTF Printers: Counterweight and Bracket Design Adapted to Different Widths

According to the width and application scenarios of DTF printers, the industry has formed a clear hierarchical stability scheme to help DTF printer users with different needs select suitable equipment:

(I) Small DTF Printer (≤30cm Width): Bracket-Free Design, Minimalist Counterweight

Small DTF printers are mainly used for personalized small-batch printing. Their printing speed is usually lower than 0.4m/s, and the print head is relatively light (2-3kg). This type of DTF printer adopts a bracket-free structure. Shaking can be suppressed by adding 2-4kg of fixed counterweight blocks at the bottom of the machine body and combining with non-slip rubber feet.

(II) Desktop DTF Printer (30-40cm Width): External Bracket Support, Adjustable Counterweight

Desktop DTF printers are suitable for mass production in small and medium-sized studios, with a printing speed of 0.5-0.8m/s. External brackets are required to enhance stability. The angle steel welded bracket of the DTF printer is provided with 4 adjustable supporting feet at the bottom, which can fine-tune the levelness of the machine body and is installed at the opposite position of the print head movement direction. This scheme can control the shaking amplitude of the DTF printer within 0.2-0.3mm, ensuring the printing accuracy of A3+ format. The comprehensive cost of the bracket and counterweight is about 500-800 yuan, making it one of the most popular types of DTF printers on the market.

(III) Production-Grade DTF Printer (60-120cm Width): Integrated Counterweight Blocks, Chassis Shock Absorption

Production-grade DTF printers are targeted at industrial scenarios such as clothing factories, with a high printing speed of 1.0-1.2m/s. They must adopt an integrated counterweight chassis design. The chassis of the DTF printer has built-in 15-30kg cast iron counterweight blocks, which are distributed on both sides of the print head movement track according to the symmetry principle. Some high-end DTF printers also have shock-absorbing chambers in the chassis, and realize the offset of vibration force through opposite counterweight blocks connected by springs. For example, the counterweight chassis weight of a 120cm width DTF printer can reach 40% of the total weight of the equipment. Combined with the square steel welded frame, it can achieve micro-vibration operation during high-speed printing, ensuring that the DTF printer maintains the printing consistency of large-format patterns in continuous production and meets the efficient and stable needs of factories for DTF printers.

V. Quantitative Relationship Between DTF Printer Head Speed and Shaking: Mathematical Analysis Based on Dynamics

The shaking amplitude of the DTF printer has a non-linear positive correlation with the print head speed. Understanding this relationship can help DTF printer users reasonably adjust parameters and improve printing quality:

(I) Definition of Core Variables

- v: Movement speed of the DTF printer’s print head (m/s)

- m: Mass of the DTF printer’s print head (kg)

- M: Total mass of the DTF printer equipment (kg)

- k: Rigidity coefficient of the DTF printer base (N/m)

- A: Shaking amplitude of the DTF printer (mm)

(II) Mathematical Model Construction

When the print head of the DTF printer moves in a reciprocating linear motion at speed v, the generated inertial force F=ma (a is acceleration). In the uniform speed stage, the inertial force mainly comes from the impact when the direction changes. According to the mechanical vibration theory, the relationship between the shaking amplitude A of the DTF printer and the speed v can be expressed as:

A = (k1×v²×m) / (k×M)

Among them, k1 is a correction coefficient (related to the clearance of the DTF printer’s movement mechanism and lubrication state, with a value of 0.05-0.12).

(III) Practical Application Verification

Taking a desktop DTF printer with a width of 40cm as an example, m=5kg, M=80kg, k=20000N/m, k1=0.08:

- When v=0.5m/s, A=(0.08×0.25×5)/(20000×80)=0.1/1600000=0.0625mm

- When v=0.8m/s, A=(0.08×0.64×5)/(20000×80)=0.256/1600000=0.16mm

- When v=1.0m/s, A=(0.08×1×5)/(20000×80)=0.4/1600000=0.25mm

This model clearly shows that when the speed of the DTF printer increases from 0.5m/s to 1.0m/s, the shaking amplitude increases by 4 times. This also explains why production-grade DTF printers must control the balance between speed and shaking through heavy counterweights. At the same time, when the total mass (M) of the DTF printer increases, the shaking amplitude (A) will decrease significantly, which confirms the core value of the DTF printer’s counterweight design.

VI. Case Empirical Study: Counterweight Optimization Scheme of Keditec60 Series DTF Printers

As a representative model of DTF printers with a width of 60cm, the Keditec60 series has a very valuable design in terms of shaking suppression, which can help DTF printer users understand the advantages of high-quality counterweight schemes:

(I) Integrated Counterweight Chassis Design

The total weight of the Keditec60 series DTF printer reaches 320kg, among which the counterweight chassis accounts for 35% (about 112kg). It is formed by one-time casting of high-density cast iron. The bottom of the chassis is provided with 6 evenly distributed supporting feet, which controls the height of the machine’s center of gravity below 50cm, 20% lower than that of traditional DTF printers. This low-center-of-gravity design greatly improves the anti-toppling torque of the DTF printer. Combined with the reinforcing structure inside the chassis, the rigidity coefficient of the DTF printer base is increased to more than 35000N/m, reducing the shaking hidden danger of the DTF printer from the structure.

(II) Dynamic Balance System

For the print head (mass 7kg) of the 60cm width DTF printer, the Keditec60 series DTF printer is equipped with 4 sets of adjustable counterweight blocks on both sides of the print head movement track. Through accurate calculation using the inertial torque balance method, each set of counterweight blocks has a mass of 5kg, and the position can be fine-tuned according to the printing speed (0.6-1.0m/s) of the DTF printer. When the DTF printer’s print head runs at a speed of 1.0m/s, the shaking amplitude can be controlled within 0.12mm, 65% lower than that of similar DTF printers without counterweights, ensuring the printing accuracy of the DTF printer.

(III) Shock Absorption and Transmission Optimization

The connection between the chassis and the machine body of the Keditec60 series DTF printer adopts rubber buffer pads, which can absorb 30% of the vibration energy. At the same time, a suction type rolling transport shaft is used to reduce the resonance interference between the PET film transmission and the DTF printer’s print head movement. Practical tests show that after 8 hours of continuous high-speed printing, the pattern positioning deviation of this DTF printer is always less than 0.2mm, which fully meets the high-precision requirements of the garment printing industry for DTF printers and is a recommended high-quality DTF printer model.

Conclusion

The shaking problem of DTF printers is essentially a systematic problem of mechanical structure and dynamic balance. To solve this problem, it is necessary to start from three dimensions: the rigidity design of the DTF printer base, the scientific calculation of the counterweight, and the adaptation of hierarchical schemes. For DTF printer users, small-sized models can meet the needs by adding basic counterweights, desktop models need to be equipped with external brackets and adjustable counterweights, while production-grade models must choose high-end DTF printers with integrated counterweight chassis. The practice of the Keditec60 series DTF printers shows that a reasonable counterweight design can not only effectively suppress the shaking of the DTF printer but also improve the long-term stability and printing accuracy of the DTF printer, creating higher production value for DTF printer users.