Work progress of Keditec DTF R&D Center: Powder-shake-free printer is coming, and over 40 glue tests break through industry pain points

1. Key Progress of Keditec's R&D DTF Center: Debris-free Printer Debuts, Adhesive Testing Strengthens Technical Foundation

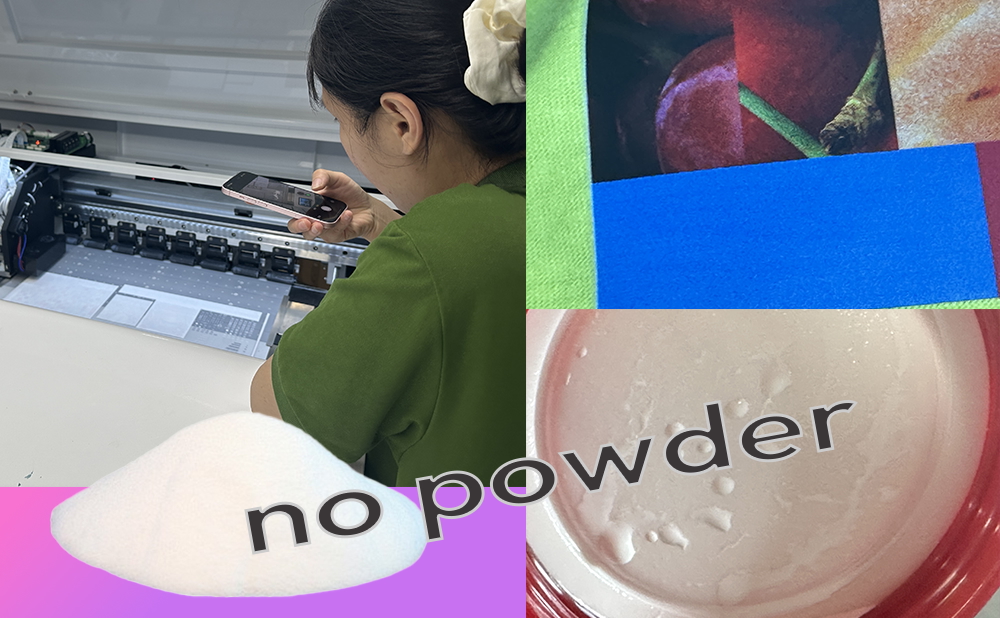

In the traditional process of DTF technology, the “powder shaking” step (i.e., evenly covering the printed pattern with DTF powder through equipment) is crucial for achieving the fastness of the print, but it also has problems such as complex operation and powder waste. However, the “powder-shaking-free printer” promoted by Keditec’s DTF R&D Center is aimed at this pain point – through technological innovation, it eliminates the “powder shaking” step, aiming to simplify the production process, reduce costs, and improve printing efficiency.

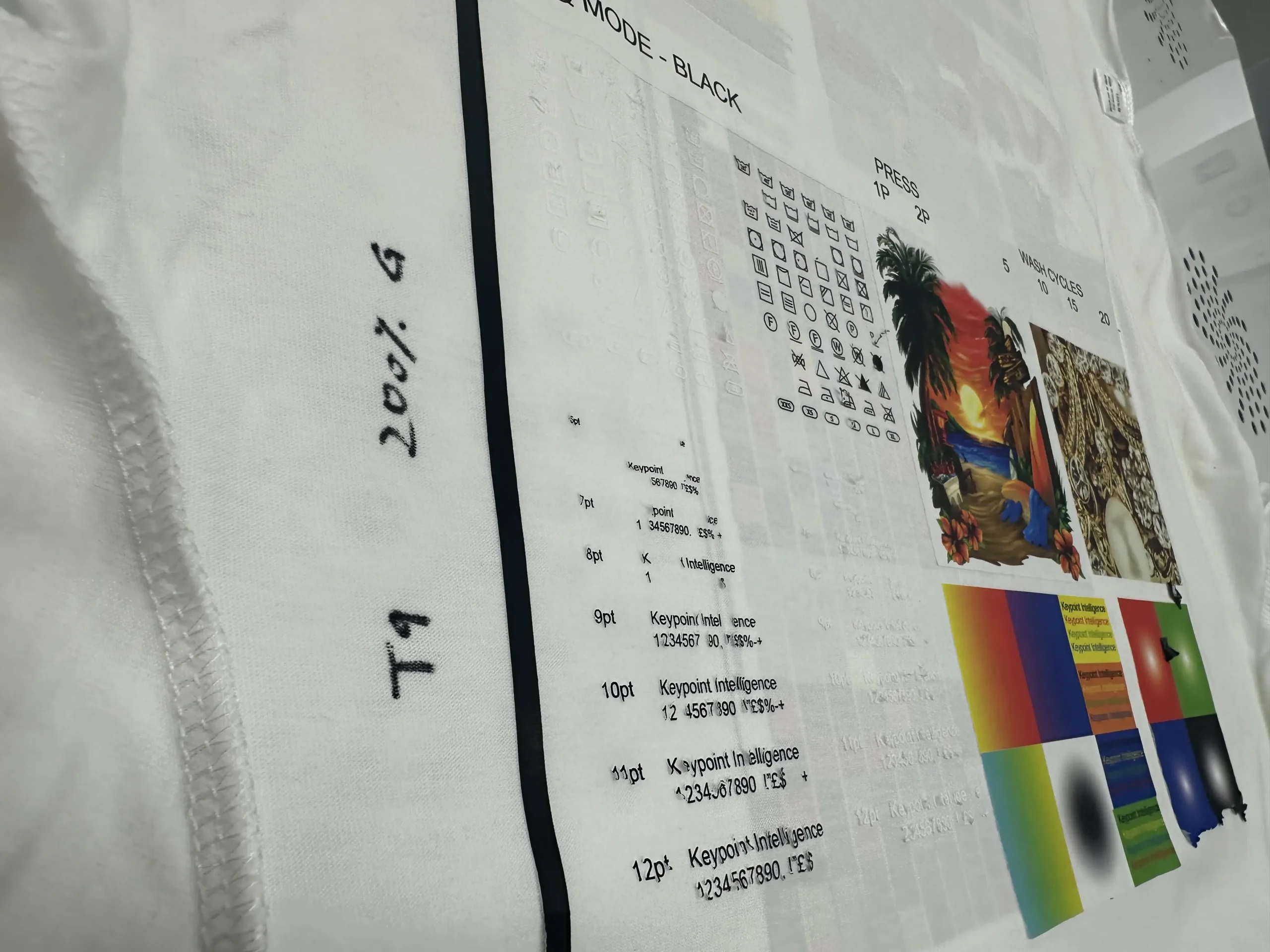

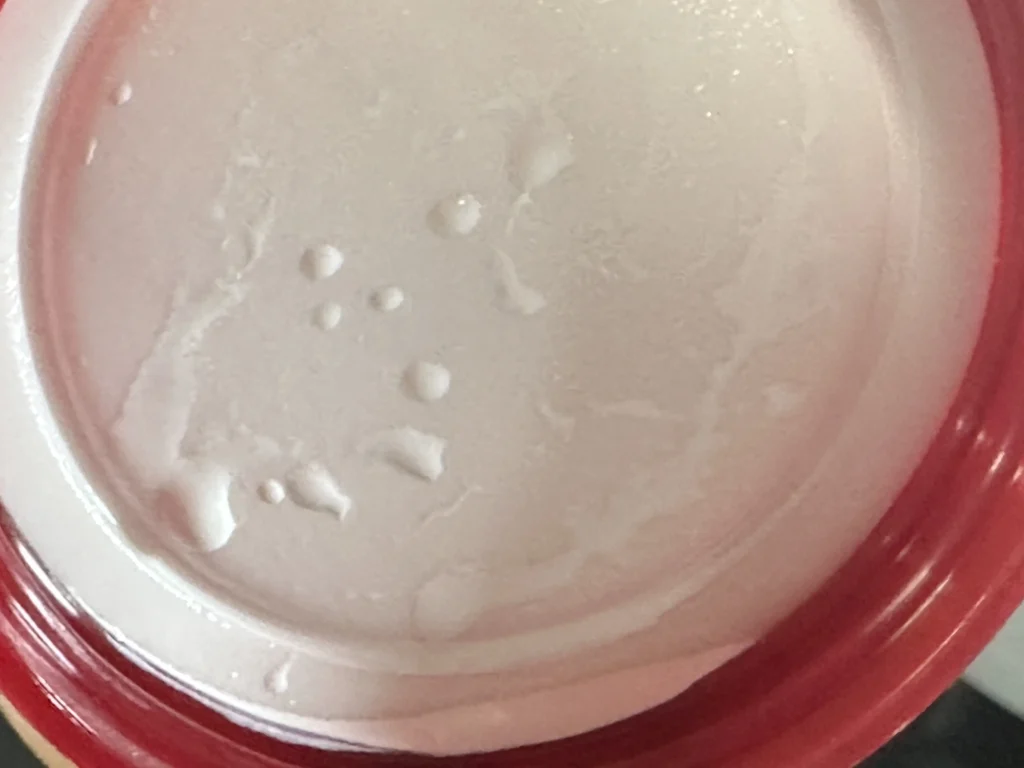

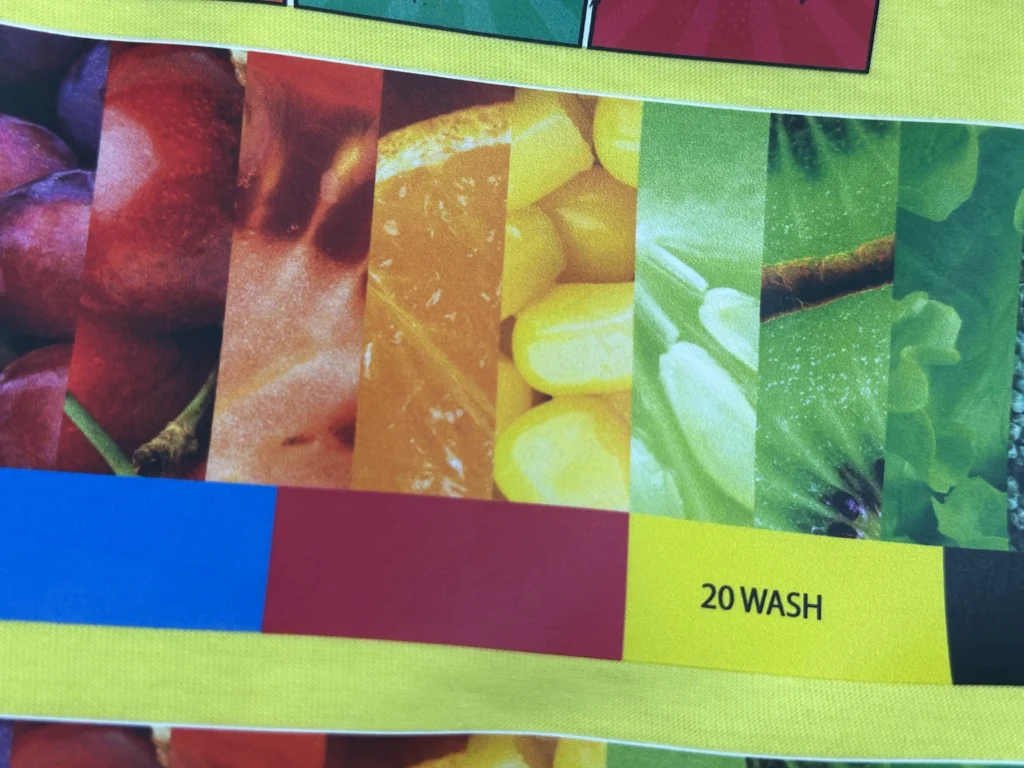

To meet the technical requirements of the powder-shaking-free printer, the laboratory support team of the R&D center has launched high-intensity testing work: targeting more than 40 different formulations and brands of DTF adhesives on the market, testing them from three core dimensions: “compatibility”, “durability”, and “nozzle friendliness”. According to laboratory staff, each adhesive needs to undergo at least 50 actual printing tests, recording data such as drying speed, adhesion, and compatibility with printing inks, and finally selecting the optimal adhesive solution suitable for powder-shaking-free technology. This testing process is not only time-consuming and labor-intensive but also requires a high degree of rigor – the performance of the adhesive directly determines the final effect of the powder-shaking-free printer and is also the core prerequisite for the subsequent implementation of the technology.

II. John's Perspective: The "Breaking" and "Establishing" of powder shaker-free DTF Technology, Why Reconstruct Traditional Processes?

As a practitioner who has long followed the development of DTF technology, I (John) believe that Keditec’s promotion of抖粉-free printers is essentially a “reconstruction” of the traditional DTF process. To understand the necessity of this transformation, we need to start with the underlying technical logic and the pain points of the industry:

1. White ink and DTF powder: the "(essential needs)" of traditional DTF technology, but with hidden limitations

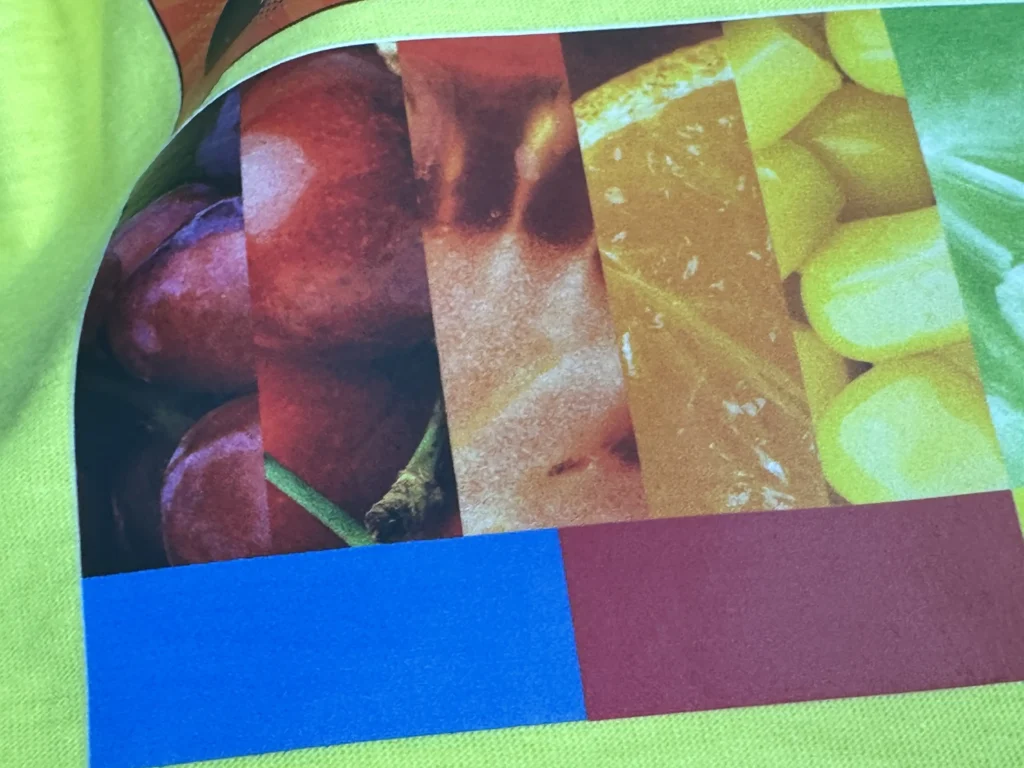

In the traditional DTF process, “white ink” and “DTF powder” are the two core elements: white ink is used to present clear patterns on dark fabrics, while DTF powder (mainly composed of hot-melt adhesive powder) adheres to the fabric through heating to ensure that the printed patterns do not fall off. Although the combination of the two can meet basic printing needs, problems arise – the storage of powder requires a moisture-proof environment, it is prone to dust pollution during use, and the powder waste rate is as high as 15% to 20%, which not only increases costs but also does not conform to the environmental protection trend.

2. Gradually replacing powder: driven by both environmental protection and efficiency

Why is Keditec promoting “powder-free” technology to gradually replace traditional powder? It stems from two core demands:

1. Environmental factors: The dust generated in the traditional powder shaking process not only affects the air quality in the workshop but may also have an impact on the health of operators with long-term exposure. Meanwhile, the disposal of waste powder will increase the environmental protection costs of enterprises, which is contrary to the industry trend of “green production”.

2. Process simplification: “Powder shaking” requires special equipment (powder shakers) and operators, and the thickness and uniformity of the powder must be strictly controlled. Even a slight deviation can lead to printing defects. The powder-free technology directly eliminates this step through the optimization of glue formulations and equipment improvement, which can not only reduce equipment investment but also lower the difficulty of manual operations, allowing small and medium-sized manufacturers to easily get started with DTF printing.

3. Current Status of DTF Printers Without Shaking Powder: Amid Opportunities, Three Major Concerns Become Industry "Stumbling Blocks"

III. Laboratory Interview: Kity Explains the Core Connection Between Glue and Anti-Shake Powder Technology

To further understand Keditec's breakthroughs in anti-powder shaking technology, I (John) specially interviewed Kity, a staff member of the R&D Center Laboratory, and conducted a dialogue focusing on the core issues of concern to the industry:

Question 1: How much impact does the current glue have on the printer nozzle?

Kity: The impact is very significant, and this is one of the core reasons why we tested over forty types of glue. Currently, many brands of powder-free DTF printers on the market completely avoid mentioning “the damage that glue causes to printheads” in their promotions. It’s not that they haven’t noticed it, but that they deliberately avoid it. On one hand, they haven’t made adaptive optimizations for glue and thus cannot solve the problem of printhead clogging. On the other hand, if they truthfully inform customers of the risk of printhead damage, it will reduce customers’ purchasing willingness. However, for Keditec, printhead damage is a core cost for users, so we must avoid it during the research and development stage through glue selection and equipment improvements.

Question 2: What is the current level of the glue performance in Keditec Laboratory?

Kity: The research and development process involves technical confidentiality, and I hope everyone can understand this. However, what can be made clear is that the current glue testing and formula optimization are going smoothly. Our R&D team adjusts the glue composition every day based on test data. For example, they reduce the viscosity to minimize nozzle clogging, while increasing the adhesive strength to ensure durability. What we can guarantee is that we have not stopped improving, and the final glue solution launched will definitely meet the requirements of “low loss and high durability”.

Question 3: Is the difference between powdered and powder-free simply "glue replacing powder"?

Kity: Of course not. Many people think that the powder-free shaking technology is just “removing the powder and changing the glue”, but in fact, it involves systematic improvements to the entire machine model. For example, the “powder shaking bin” of traditional DTF equipment needs to be replaced with a “heating plate” adapted to the powder-free shaking technology — through precise temperature control, the glue is quickly cured, replacing the original logic of “powder heating and bonding”; in addition, the paper feeding speed of the printer and the ink jet pressure also need to be re-adjusted to ensure that the glue and ink can be perfectly integrated and avoid pattern blurring. It can be said that the powder-free shaking printer is a complete solution of “equipment + glue + ink”. If any link fails to keep up, the ideal effect cannot be achieved.

IV. Summary: Keditec's powder shaker-free DTF technology provides a new path for "cost reduction and efficiency improvement" in the industry.

Judging from the progress of Keditec’s R&D DTF Center, the powder-shake-free printer is not a “conceptual product” but a substantial breakthrough based on industry pain points. The testing of more than 40 types of adhesives demonstrates the control over “details”, while the supporting improvements of the machine models and adhesives show “systematic thinking”.

For the industry, Keditec’s exploration is of great significance. On the one hand, the powder-shake-free technology eliminates the powder process, which can not only reduce environmental pressure but also lower the equipment investment and operation threshold for small and medium-sized manufacturers. On the other hand, through the optimization of adhesive formulas and the design of nozzle protection, it solves the core concerns of current powder-shake-free products and clears the obstacles for technology implementation.

In the future, with the further advancement of Keditec’s R&D, the powder-shake-free DTF printer is expected to become a new industry benchmark, driving the entire DTF field towards the direction of “more efficient, more environmentally friendly, and lower cost”. We will also continue to pay attention to the progress of the R&D center and share the latest technological developments in the first place.

Contact us