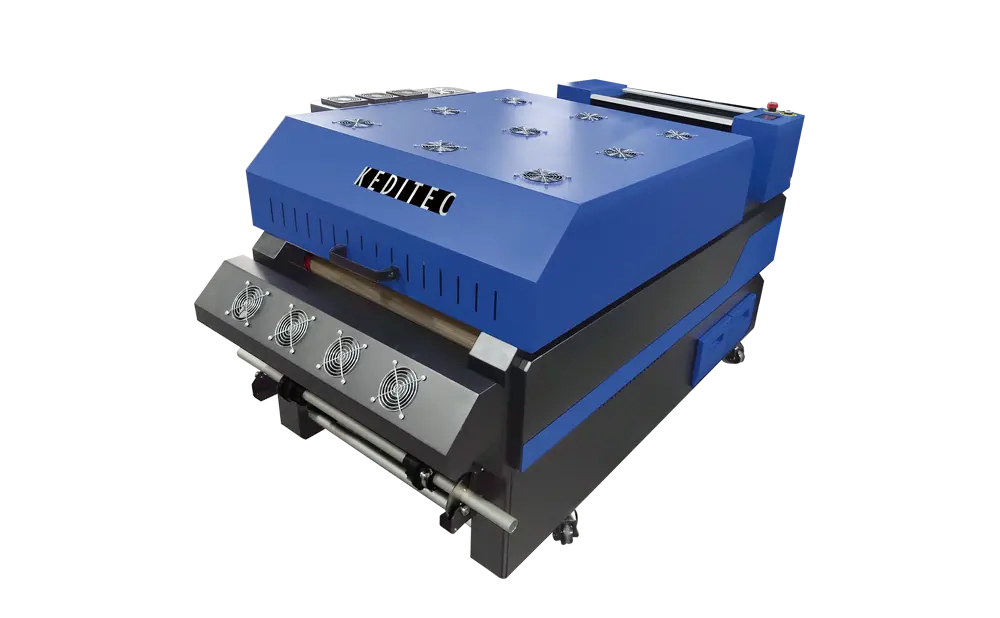

Keditec DTF Powder Shaker: An Efficient Tool for Mass Commercial Production

Update date: 2025-7-31

In the wave of vigorous development of DTF printer technology, the innovative combination of white ink and powder has brought a revolutionary breakthrough to the clothing printing industry. The powder shaker has also emerged as a key device for the practical application of this technology. Keditec powder shaker occupies an important position in the industry with its excellent performance and elaborate design.

Development History of Powder Shakers

The birth of the powder shaker is closely linked to the development of DTF printer technology. As the demand for the application of the combination of white ink and powder on clothing has grown, manual operation alone can no longer meet the production needs. The powder shaker, as a device to improve efficiency and ensure quality, has emerged and gradually become an indispensable part of mass production.

Working Principle of the Powder Shaker

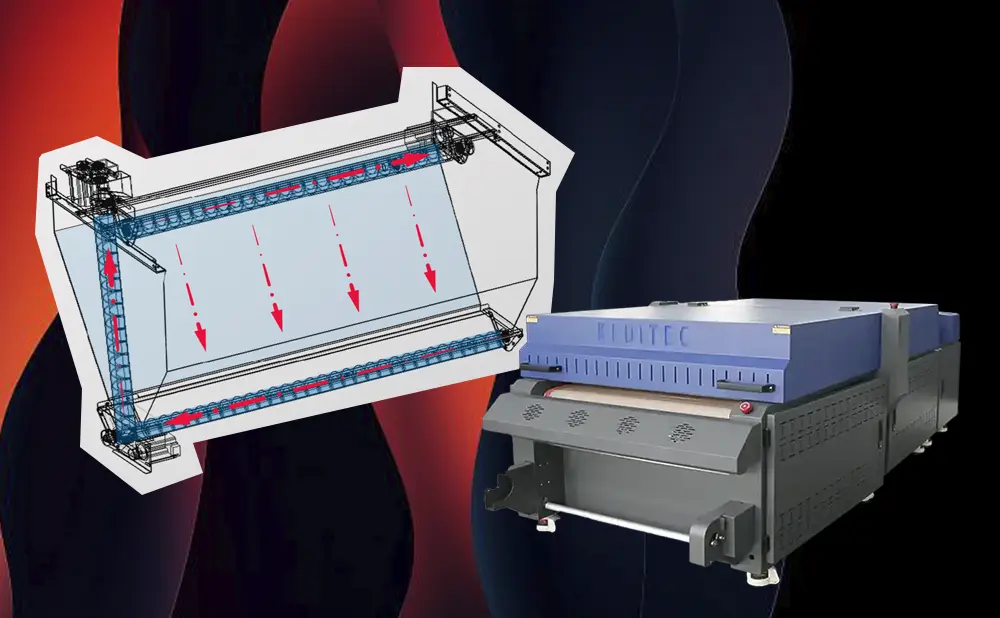

The powder in Keditec powder shaker is discharged quantitatively each time through an aluminum gear lever. Before the film enters the oven layer, the transmission shaking lever will 拍打 the film at high frequency to make the excess powder fall off for recycling. Then, it enters the powder shaking oven conveyor belt.

To achieve uniform heating inside the oven, heat pipes and reflective mirrors are designed to achieve cross heating. Through precise calculation, the heat value and temperature are stabilized within the range set by the customer. The built-in precision temperature sensor feeds back the temperature information to the monitoring panel to ensure precise temperature control.

Comparison of Powder Shaker Designs on the Market

Unique Designs and Advantages of Keditec Powder Shaker

Applicable Scenarios of Powder Shakers

A powder shaker is an efficient tool for mass commercial production, suitable for enterprises or merchants that need large-scale production. If you are just a personal apprentice, it is not worthwhile to spend money on a powder shaker. For apprentices, it is recommended to use manual powder shaking together with Keditec’s small oven.

Summary

With its advanced built-in smoke exhaust system, efficient dual filtration and separation system, precise temperature control design, convenient touch operation, stable fuselage structure, comprehensive safety protection and many other advantages, Keditec powder shaker has become an ideal choice for mass commercial production.

It can not only improve production efficiency and ensure product quality but also perform excellently in environmental protection and safety, providing strong support for the development of industries such as clothing printing. For practitioners with mass production needs, Keditec powder shaker is undoubtedly a reliable and efficient device.

An overview of the Douyin follower machines currently on sale by keditec

Keditec 30 DTF powder shaker

Keditec 42 DTF powder shaker

Keditec 60 DTF powder shaker

Keditec 60 DTF pro powder shaker

Keditec 80 DTF powder shaker

Keditec 90 DTF powder shaker

Keditec 120 DTF powder shaker

Contact us