Guide to White Ink Heat Transfer "Film"

Basic product introduction information

describe

Production process

parameter

Basement membrane thickness:75um

Regular size:A3、A4、 30/40/60/120cm*100m

Regular packaging:1/2/4 pack/box;100page/Box,A3/10pack /box

Production process

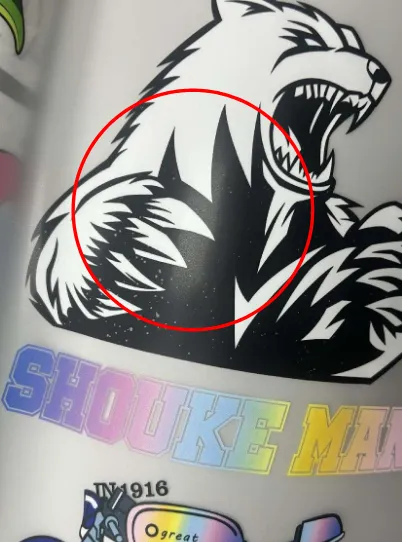

Advantage

1

2

3

4

Classification

Single-sided film

Double-sided film

| cold peel film | Hot tear film | Second-tear film | |

| Advantages | The most stable, bright colors, and good fastness | Can be torn hot or cold, stable, and the operation efficiency is higher than cold tearing. | It can be peeled off at all times and can be torn off when cold or hot, so as to reduce the customer’s stock pressure and achieve high efficiency. |

| Disadvantage | Low operational efficiency | It cannot be peeled off immediately after ironing. | The color and fastness are slightly inferior to those of cold peeling. |

| market | Silk screen printing, high-end offset conversion clients | Customers converted from offset heat transfer printing, e-commerce customers, customers who pursue simplicity and efficiency | E-commerce customers pursue efficiency and stability |

Instructions for Use

Working environment

Temperature: 26-28℃

Humidity: <50%RH

Set printing parameters

Printer platform temperature: room temperature / heating 35-60℃

Dried bean jelly drying

Set the shake powder intensity: weak, medium, strong. Debug according to the pattern. Small characters can reduce the intensity.

Temperature: normal temperature – 100℃

Temperature zones: 2 ovens (80-100/110-160)℃

1 oven (100-140)℃

Speed: match the printing speed

Ironing and Peeling

Pressure setting: 4.5-5.5kg

Temperature: 140-160℃

Time: 5-15s

Peeling time: Tear off immediately – 1s, hot peel – tear off after 10s, cold peel – tear off after cooling to room temperature.

Solutions to Common Problems

Flowing ink

Reasons:

1. The ink output of the machine is large, and the ink circuits of different machines are affected.

2. The curves are different, and the ink output of color ink is heavy.

3. The air is humid, which affects the ink absorption of the printing film.

Solutions:

1. Reduce the amount of white ink dispensed.

2. Increase the heating temperature of the printer platform to help activate the ink and reduce ink bleeding.

Edge Blur

Reasons:

1. Excessive exudation of glycerin or humectant in the ink

2. Humid weather affects the ink absorption of the film

Solutions:

Increase the heating temperature of the front baffle of the (shaker machine) and the printer platform.

sticky powder

Reasons:

1. The membrane is damp

2. The powder is damp

3. The air environment is humid

4. The machine’s static elimination is not handled properly

Solutions:

1. Conduct a powder adhesion test on the unprinted film. If the film adheres to powder, the film is damp.

2. If the powder is damp, replace the hot-melt powder and retest.

3. Control the temperature at 26℃-28℃ and the humidity below 50%.

4. Ground the machine and adjust the surrounding electrical facilities properly.

Drying and wrinkling

Reason:

The oven temperature is too high

Solutions:

Lower the baking temperature of the powder shaking machine

Burn through

Reason:

The baking temperature is too high, causing the temperature of moisture and ink to rise suddenly, which leads to the pattern bursting.

Solutions:

Appropriately lower the baking temperature of the powder shaker, reduce the temperature difference between the front and back, and gradually thoroughly bake off the oil and water, melt the glue without causing violent reactions.

oil return

Reasons:

1. The oven temperature is insufficient, and the film is not fully dried.

2. Excessive glycerin or diluent in the ink volatilizes.

Solutions:

1. Increase the baking temperature

2. Check the ink compatibility

Difficult to peel off

Reasons:

1. The preheating temperature is too high, resulting in failure to adhere to the hot-melt powder.

2. The ironing temperature is insufficient, causing the hot-melt powder to not fully melt.

3. The pressure of the ironing machine is insufficient.

Solutions:

1. Appropriately lower the temperature of the front baffle and the printer.

2. Appropriately increase the temperature of the ironing machine or extend the ironing time.

3. Appropriately increase the pressure of the ironing machine.

Storage and Precautions

Storage and Expiration Date

1. Storage conditions: Store in a cool and dry place, and strictly prohibit collision with sharp objects. If the package is opened and not used up, please seal it before storing to prevent moisture and high temperature. Optimal storage conditions: temperature 26℃-28℃, humidity <50%.

2. Shelf life: Under the condition that the product is well-packaged, unopened and stored normally, the shelf life is 180 days. Products beyond the shelf life can continue to be used after passing the inspection.

Other precautions

1. Due to differences in printers, inks, ICC curves of boards, and substrate fabrics among different users, adjustments can be made according to actual situations.

2. If the film surface is exposed to moisture or dust for a long time, the exposed section should be discarded before printing to ensure the printing effect.

3. Handle the film roll with care, avoid crushing and bruising. When cutting the wrapping film, pay attention to the strength and angle of the tool to prevent deep scratches.

Contact us