2025: Are You Still Doing DTF Heat Pressing Manually?

In 2025, as demand for personalized printing booms, DTF (Direct-to-Film) technology has become a core choice for small and medium-sized businesses producing custom clothing and accessories. But if your production line still relies on manual operation for the heat-press stage—cumbersome, inefficient, and prone to quality fluctuations—you might already be falling behind the industry. As technology advances, electric, intelligent heat presses are redefining DTF production efficiency. It’s time to bid farewell to the “manual era.”

Update date: 2025-7-31

First, let’s clarify: Why can’t DTF work without a heat press?

The core principle of DTF is straightforward: Design patterns are first printed onto DTF transfer film using specialized inks. Then, through the heat-press process, the ink on the film is transferred and cured onto the fabric (or other materials) under high temperature and pressure, ultimately forming a durable pattern.

The heat press is the “final critical step” in the DTF process. Its role is to precisely provide temperature, pressure, and time: High temperature activates the ink and allows it to penetrate the fabric; pressure ensures tight bonding between the ink and fabric; and sufficient time guarantees curing effect—all three are indispensable, directly determining the pattern’s adhesion, color reproduction, and wash resistance. Without a heat press, DTF “transfer” would be impossible.

The core principle of a heat press: A balanced triangle of “temperature control, pressure application, and timing”

The working logic of a heat press is simple: A built-in heating plate (usually aluminum alloy for uniform heat conduction) raises the temperature to a set value (160-180°C is common for DTF). Then, mechanical structures (manual, pneumatic, or electric) apply pressure to the pressing surface (typically 3-8kg/cm²) and maintain it for a set duration (10-30 seconds).

In short, it’s about “using heat to open the fabric fibers’ ‘reception channels,’ using pressure to push the ink ‘in,’ and using time to ‘lock’ the ink with the fabric.” However, the stability of these three parameters is precisely the weakness of manual heat presses—with manual operation, pressure fluctuates, temperature control is imprecise, and timing relies on guesswork, easily leading to peeling patterns or dull colors.

Types of heat presses on the market: How do efficiency differ from “manual” to “multi-station”?

Currently, heat presses on the market fall into four main categories, each with distinct use cases and limitations:

- Manual heat presses: The most basic type, relying on manual lever operation for pressure. Temperature is adjusted via knobs, and timing depends entirely on experience. Advantages include low cost (single-station models around $800-$1,200), but efficiency is extremely low (max 30 pieces per hour), with uneven pressure and unstable quality—suitable for hobbyists or micro-orders with monthly output under 500 pieces.

- Single-station electric/pneumatic heat presses: Feature automatic temperature and timing control, with pressure driven by motors or air cylinders, improving stability. However, they can only press one piece at a time, suitable for small-batch production (1,000-3,000 pieces/month), with efficiency limited by single-station turnover.

- Dual-station heat presses: Two pressing surfaces work alternately (one presses while the other loads), boosting efficiency by over 60% compared to single-station models. But manual dual-station units still require frequent manual switching, and pressure control depends on operator skill, with prices mostly between $1,700-$2,000.

- Rotary multi-station heat presses: 3-6 stations rotate around a turntable, enabling a streamlined “loading-pressing-unloading” process, suitable for large-scale production (10,000+ pieces/month). However, they are bulky, costly (often over $5,000), and require dedicated staff to coordinate stations, making them unsuitable for small businesses.

Keditec Electric Heat Press: Why choose “electric drive”?

In 2025, as DTF production moves toward standardization, the core advantage of Keditec’s electric heat press lies in its “electric drive.”

Traditional manual or pneumatic heat presses either rely on human effort (tiring and unstable) or air sources (cumbersome to install, with pressure affected by air pressure fluctuations). Electric drive, via precision motor control, achieves 0.1kg pressure adjustment accuracy and ±1°C temperature control, fundamentally eliminating “human error” and “environmental interference.”

More importantly, electric drive requires no external air supply—just plug it in and use, with extremely low installation barriers. It also consumes only 1/3 of the energy of pneumatic equipment, saving costs in long-term use.

Electric control: Three-fold advantages of labor savings, efficiency, and standardization

For small and medium-sized businesses, electric control brings transformative changes:

- Labor-saving: No more relying on “brute force” for pressing. Operators only need to load materials and press the start button; the motor automatically completes pressure application, holding, and release. One person can easily manage 2-3 devices, cutting labor costs by 50%.

- Faster efficiency: Dual-station design + electric automation allows 80-100 pieces per hour, 40% faster than manual dual-station models, with no need for frequent breaks (avoiding the physical exhaustion of manual operation).

- Standardization: Electronic programs strictly enforce “temperature-pressure-time” parameters. Whether operated by different people or at different times of the day, every piece achieves identical heat-press results, eliminating the problem of “some pieces lasting, some peeling” in the same batch.

Keditec DTF Heat Press: An “intelligent tool” even beginners can master

Beyond core electric drive, Keditec excels in “user-friendly” details:

- iPhone-like touch control: Equipped with a high-definition touch screen, parameters like temperature, pressure, and time are set with direct clicks, accurate to 1°C, 0.1kg, and 1 second. The interface is as intuitive as a smartphone, allowing beginners to master it in 5 minutes.

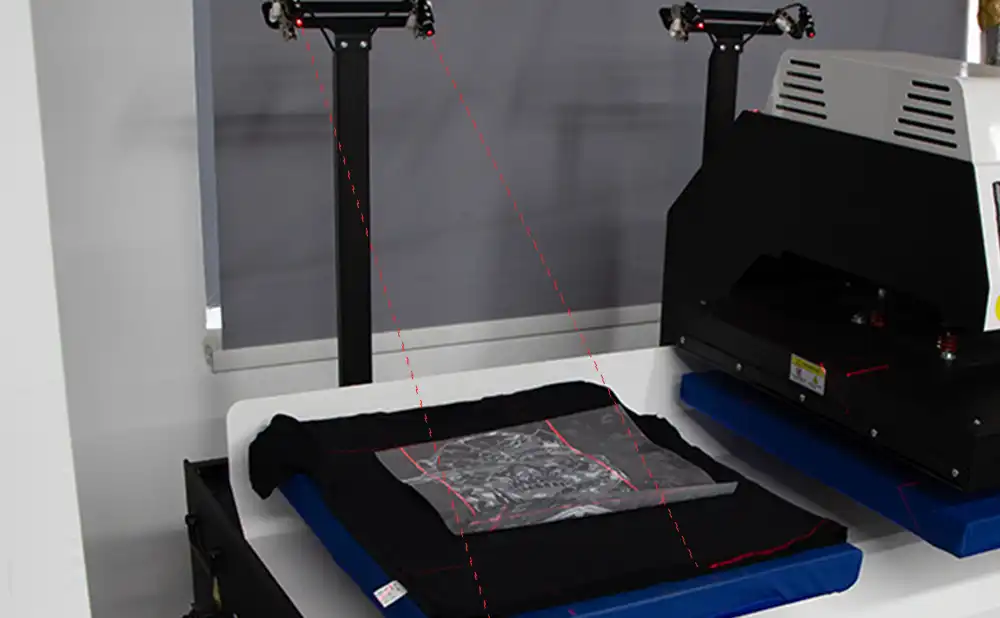

- Laser-assisted alignment: Built-in cross laser positioning lines enable easy alignment of fabric and transfer film at a glance, preventing pattern misalignment – especially for irregular parts like hats and cuffs – and tripling alignment efficiency.

- Intelligent protection: Auto-sleeps after inactivity (saving energy), alarms for abnormal temperatures, and auto-relieves pressure if too high, preventing equipment damage and safety hazards.

Price advantage: More cost-effective than manual dual-station models—inquires welcome!

Surprisingly, this heat press, combining “electric drive, intelligent control, and dual-station efficiency,” is priced far lower than similar market products. Compared to manual dual-station models at $1,700-$2,000, Keditec’s electric heat press offers a significant price advantage (specific quotes available via direct inquiry), allowing small businesses to enjoy industrial production standards at an “entry-level budget.”

Technical support: Full assistance, no worries

Choosing Keditec means more than just buying equipment:

- Free installation guidance and operation training (online + offline options);

- 1-year warranty on core components, with lifetime technical consultation;

- Regular firmware updates to optimize equipment performance;

- Dedicated customer service available 7×12 hours to resolve any production issues.

Conclusion: In 2025, it’s time to “upgrade” your heat press

The appeal of DTF technology lies in “small batches and high customization,” but inefficient, unstable manual heat pressing is eroding this advantage. In 2025, while competitors use electric heat presses to achieve “one person managing multiple machines with consistent quality,” clinging to manual operation will only trap you in “high costs, slow delivery, and poor reviews.”

Keditec’s electric heat press solves stability issues with “electric drive,” lowers operational barriers with “intelligent control,” and breaks cost barriers with “price advantage.” Instead of wasting profits on manual operation, take the leap and turn your heat-press stage into a competitive edge.

Contact us now for an exclusive quote and embrace the “electric era” of DTF production!

keditec Electric Hot Press - Special DTF

Configuration

- Product model : Keditec H1

- Heating method : Resistance plate heating

- Drive mode: Motor drive / Pneumatic drive

- Heating unit : Electric heating

Key features

- Electric automatic program control, elegant experience.

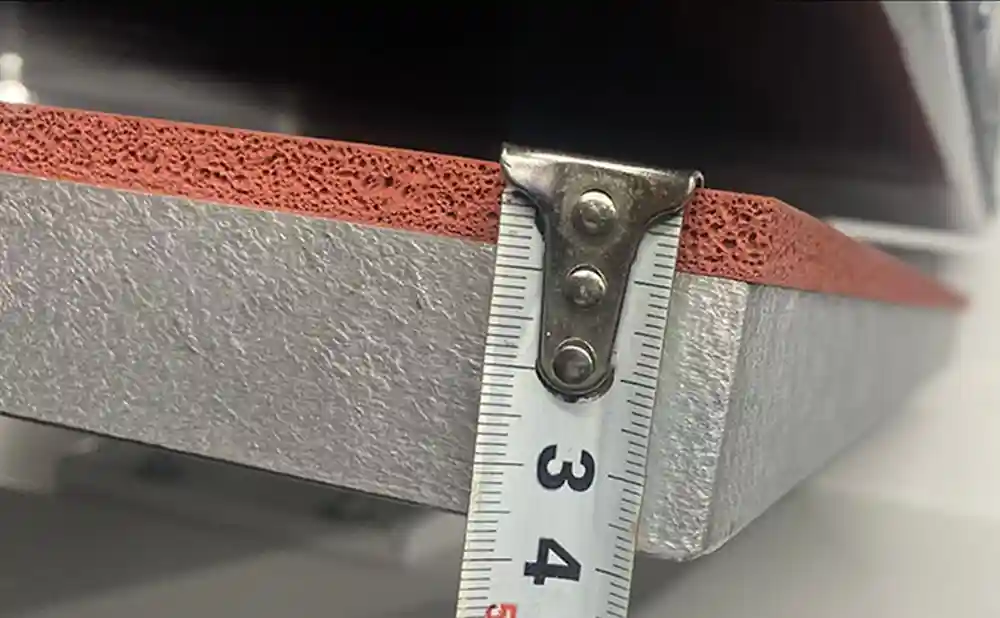

- 3CM imported aviation aluminum plate.

- The error of the center edge temperature with high flatness and uniform heating is less than ± 1 °.

- The service life is up to 20 years, and it is not easily deformed.

- With a pressure of around 800 pounds, it can be used for bonding, hot drilling, high-demand thermal sublimation, and to maintain the fabric unchanged.

- Put the clothes into the clothes, the design is convenient to put the clothes into the clothes, and the front and rear presses are placed and positioned for convenience.

Details

High definition touch screen display

High quality heating plate

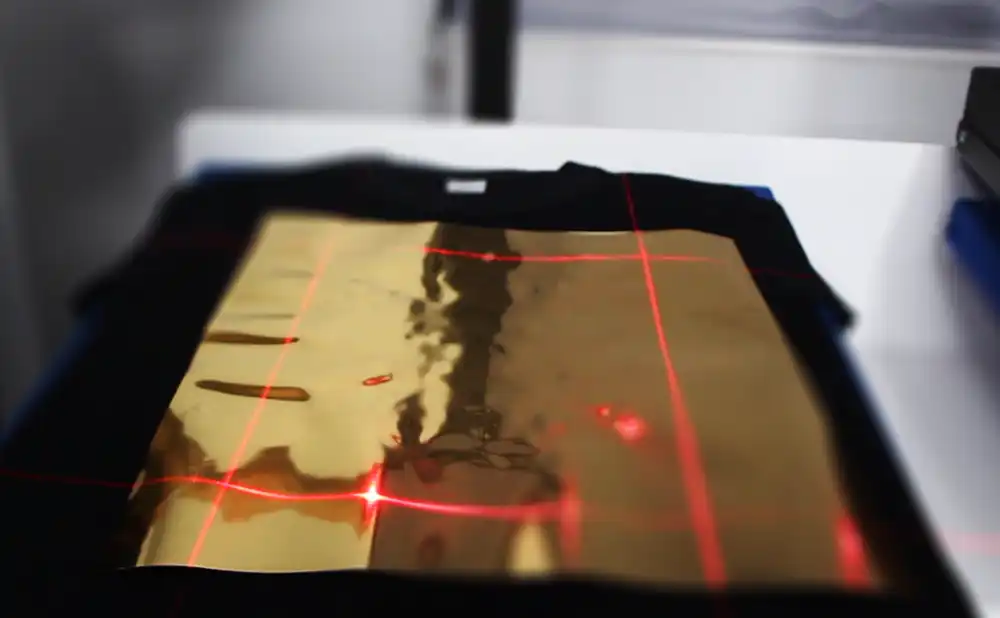

Four red laser-aligned displays

Effect on reflective materials

Cost display time

Contact us