Keditec T-shirts Printing

DTF Printing--Best Custom T-Shirt Printing Solution

The DTF printer process is widely popular and can be called a revolutionary technology. On the one hand, it has many advantages. On the one hand, it can be applied to a wide range of textiles such as cotton, silk, polyester, denim, canvas, etc. It can be printed on a variety of textiles, whether light or dark fabrics, and any clothing product.

It can effectively break the restrictions of traditional printing technology on materials. On the other hand, the printing quality is quite high, the colors are bright, and the full-color images are vivid and realistic. DTF heat transfer technology guarantees high-quality transfer effects, so that the pattern will not appear blurred or faded on clothing.

In addition, it has strong flexibility. For small shops, enthusiasts, and brands, it can easily realize small-batch clothing production to meet personalized and diverse needs. With almost no print content restrictions, anyone can print any design, providing a broad space for creativity.

Why Choosing DTF Printing On T-shirts?

Easy & Convenient Operation

DTF printing on t-shirts no need pre-treatment process, no need plate making and many other complex steps. You only need to design the printing pattern on the computer, print and powder shaking, heat press then finish down.

Versatility

DTF printing technology is widely suitable for most fabrics and colors, like Cotton, nylon, treated leather, polyester, 50/50 blends, canvas, denim and light and dark fabrics., easily handles CMYK and RGB.

Low Production Cost

In the case of small batch orders, DTF printing on tees is often much cheaper than screen printing, does not require plate making, and allows the use of an unlimited number of colors

DTG VS DTF Printing On T-shirts

If you already own a DTG printer, you are probably very familiar with the pre-treatment process. The heat-melting feature used in DTF transfers bonds the print directly to the material, which means no pre-treatment is required.

Direct-to-garment (DTG) printing is the application of digital designs directly to fabric using a DTG printer. DTG ink is very expensive and usually requires 200% white, which is the base ink for printing on black garments. White ink tends to be the most expensive, while DTF printers require less white ink, about 40%-60% white, so this printing method is more affordable, thus saving costs for our customers

On the other hand, DTG printing is slower because the pattern needs to be printed line by line. While DTF printing allows you to print multiple patterns on a single transfer film, which greatly reduces production time.

In addition, DTF printing is suitable for most fabrics, pure cotton, polyester, nylon, canvas, denim, blended fabrics, etc., While DTG is only ideal for 100% cotton T-shirt printing.

Screen Printing VS DTF Printing On T-shirts

Screen printing is a more traditional and classic process, which pushes ink through a mesh screen stencil onto the shirts. Known for its ability to produce vibrant, long-lasting prints that withstand repeated washing. Offers a unique hand feeling of the fabric. Each color of ink requires a separate screen stencil, so if you want to do a monochrome design, you can get started with low investment. The more colorful the color, the more complicated the process, which is not a good choice for designs with multiple colors unless you produce in large quantities to improve cost-effectiveness.

DTF printing is a new printing technology that prints clothing design patterns directly on PET film and then transfers them to the garment with a heat press. This technology has simple steps and colorful printing effects, and is generally popular in the T-shirt customization industry, suitable for both small-batch customization and large-scale production.

DTF Printing On T-shirts With Hot Stamping

Silk screen hot stamping is a special clothing customization process. Silk screen hot stamping adopts the golden ratio formula, which is ground and screened at high density to present a golden print with a metallic texture. The print is colorfast and washable, with a low-key and eye-catching fashion sense and a better texture.

This process is suitable for logo printing on T-shirts. How to perfectly integrate DTF and hot stamping film? keditec has recently implemented the DTF hot stamping printing solution through multiple tests of printing and washing.

How To Customized A T-shirt With DTF Printer?

DTF (direct film printing) and heat transfer technology have leaped into the printing field, and they have many advantages over traditional printing methods such as screen printing and sublimation printing. They are leaders with lower costs, faster turnaround times and wider applications. DTF Printing makes it easy to start a t-shirt business. In this video, SUBLISTAR will show you how to format art and heat press to get high-quality T-shirt products.

Popular Models For T-shirt DTF Printing

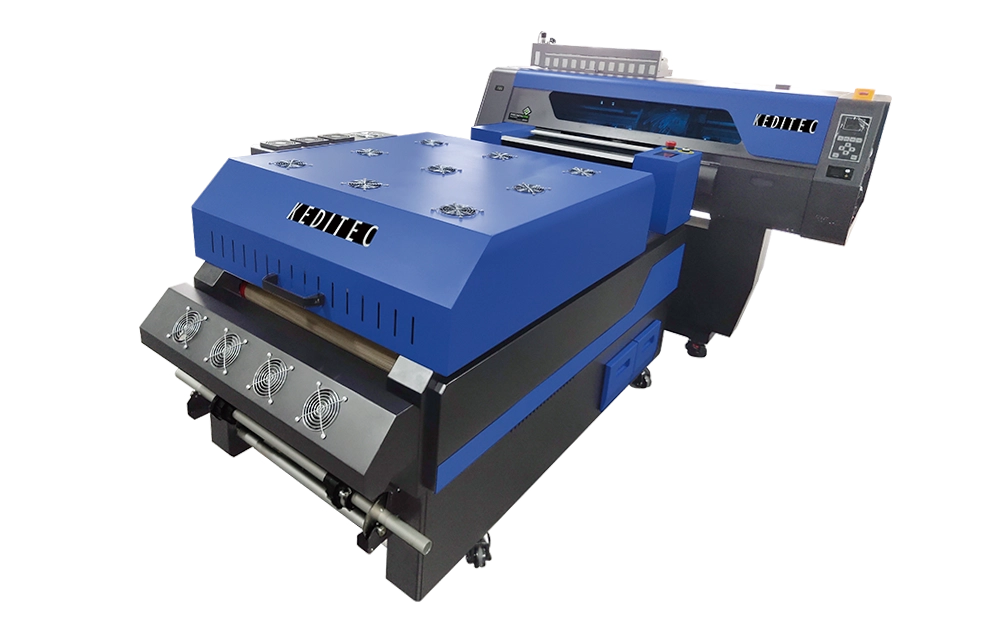

T-shirt heat transfer printing focuses on the printing effect, whether the print is clear, whether the color is full, the heat transfer quality and the washing level. This is the first concern when choosing a T-shirt printing machine.

KEDITEC DTF printers all use genunie Epson’s i-series i3200/i1600 print heads, which are accurate, with clear, vivid patterns and bright colors output.

Learn about Keditec printers

DTG printer G1

K450 – 360° inkjet printer

30 pro desktop DTF printer

Keditec 30 DTF printer

Keditec 42 DTF printer

Keditec 60 DTF printer

Contact us