Mixed flocking DTF printing

Keditec revolutionizes the use of velvet flocking dtf technology in clothing

Keditec used the characteristics of “velvet flocking film” to design patterns with three-dimensional and layered feel.

My train of thought is:

- The first step is to combine the flocking film with DTF heat transfer printing.

- The second step is to add flocked textures or three-dimensional elements to the DTF printing pattern to make the pattern more vivid.

- The third step is to print out our pattern on the back of the film, shake the powder, heat transfer to our prepared clothing, of course, you can contrast the flocking part with the printed part to achieve relief effect and enhance the visual effect.

The following are some patterns designed by Keidtec with relief effects, as well as case studies.

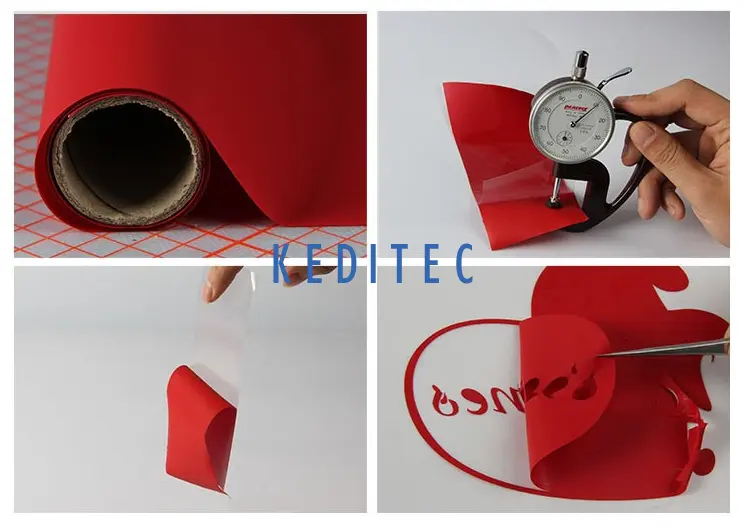

What is Velvet Flocking Thermal Transfer Vinyl Film?

Velvet Flocking Heat Transfer Vinyl is crafted from high-quality washed nylon, wool, and polyurethane.

Features :

- After being stamped at high temperature, it will not deform and is easy to engrave, cut, and remove.

- This flocking heat transfer vinyl product is suitable for a variety of different textile fabrics and has a strong hiding power.

- It presents a strong three-dimensional feel, with a soft velvet touch, bright colors, smooth and delicate feel, and will neither fall off nor fade.

- In heat transfer vinyl products, it exhibits a low-key and restrained quality.

- Flocking HTV is available in a wide range of colors and styles, which can make clothing patterns more diverse and personalized. It is an ideal choice for those who pursue clothing texture enjoyment.

- Flocking heat transfer vinyl is an environmentally friendly product that will not cause any discomfort or harm to the skin after long-term contact with the skin.

How to print flocked velvet vinyl and DTF?

As we mentioned above, using a DTF printer makes this operation much easier.

We can easily achieve this in just four steps.

- The first step is to design the pattern.

- The second step is to print the pattern.

- The third step is heat transfer.

- The fourth step is to check the effect.

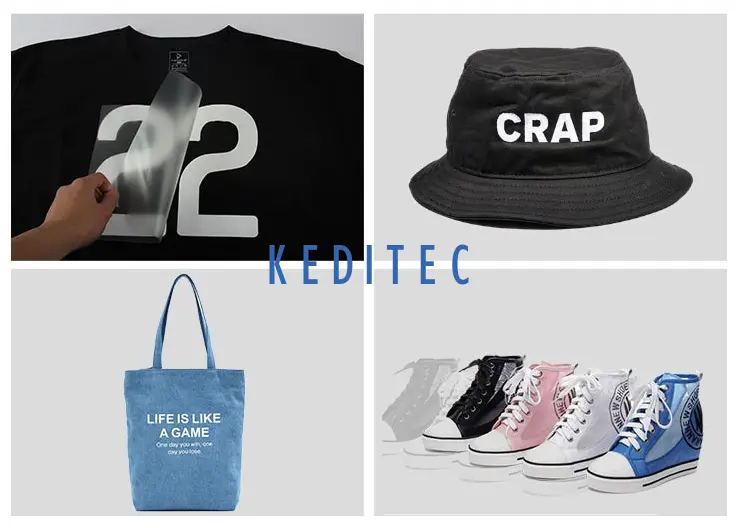

Application display

Learn about Keditec printers

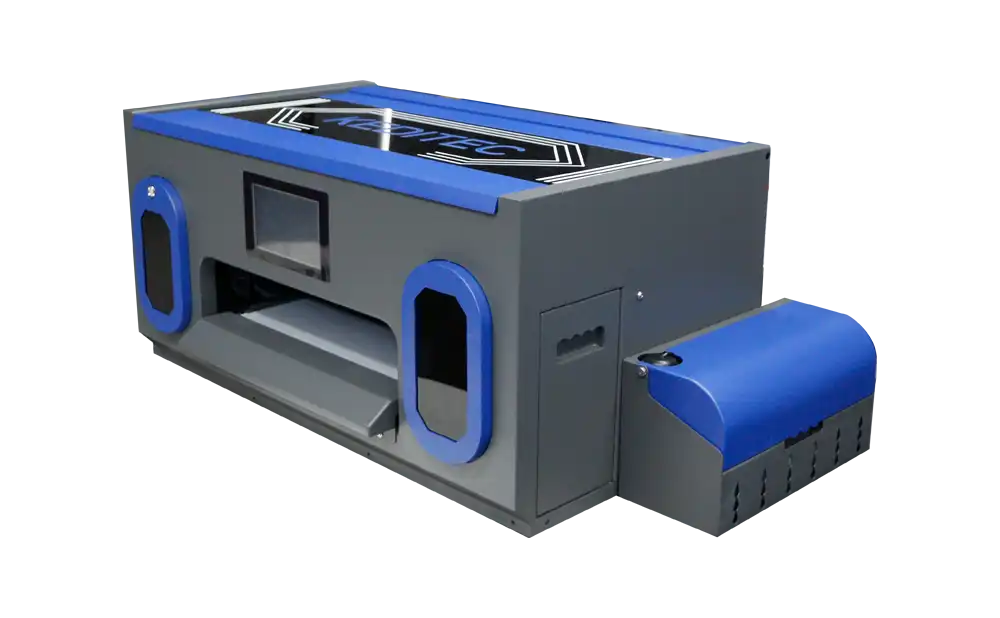

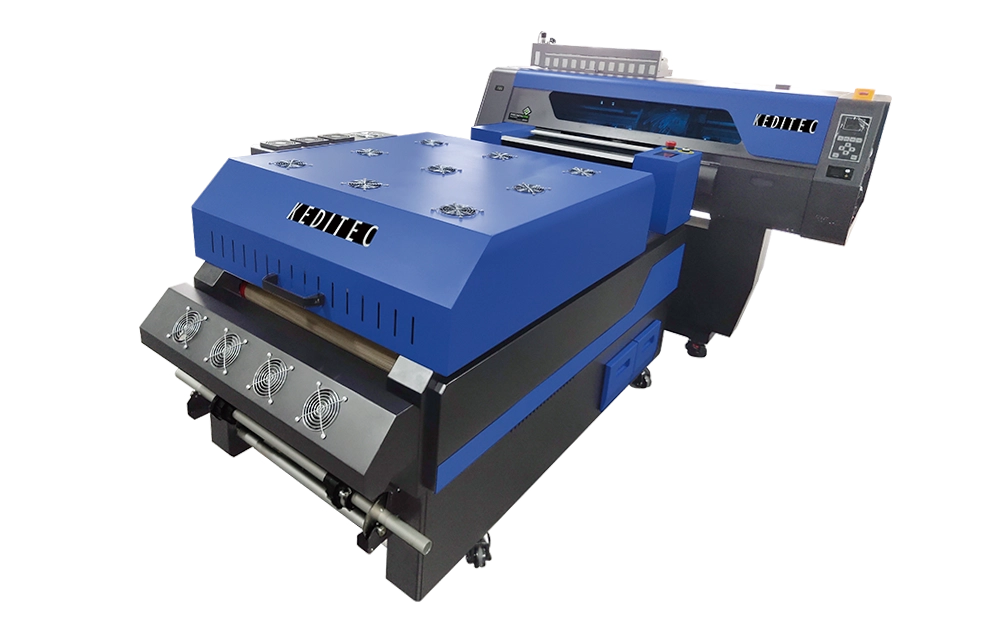

DTG printer G1

K450 – 360° inkjet printer

30 pro desktop DTF printer

Keditec 30 DTF printer

Keditec 42 DTF printer

Keditec 60 DTF printer

Contact us

🔒 All your information is secure and confidential! We won't send you spam emails.You will get our reply within 12 hours. If not please check your spam box.