Keditec DTF & imitation embroidery

Keditec creates new artificial embroidery solutions with DTF technology

Embroidery, as a traditional decoration technology, has always been loved by people. However, the traditional embroidery technology has problems such as high cost and long production cycle. The emergence of DTF printing technology for artificial embroidery has brought new development opportunities for embroidery technology.

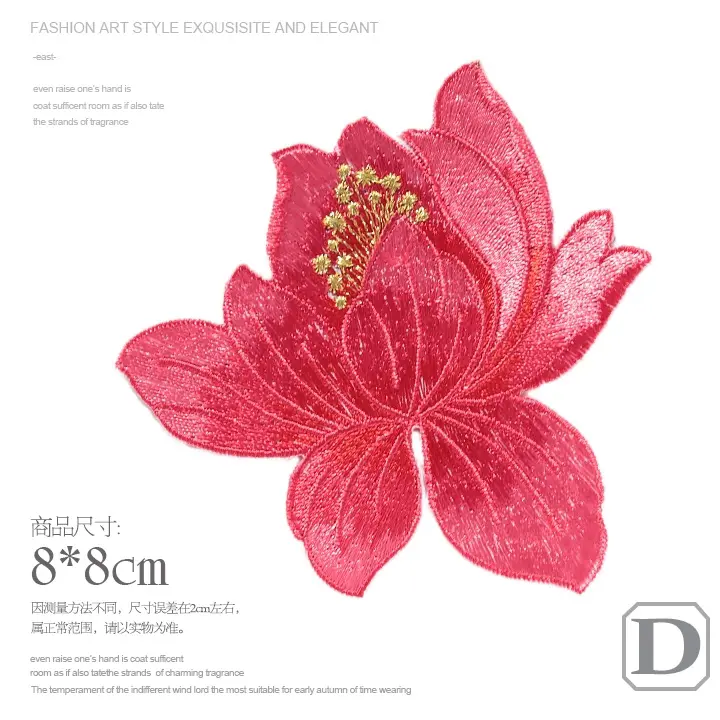

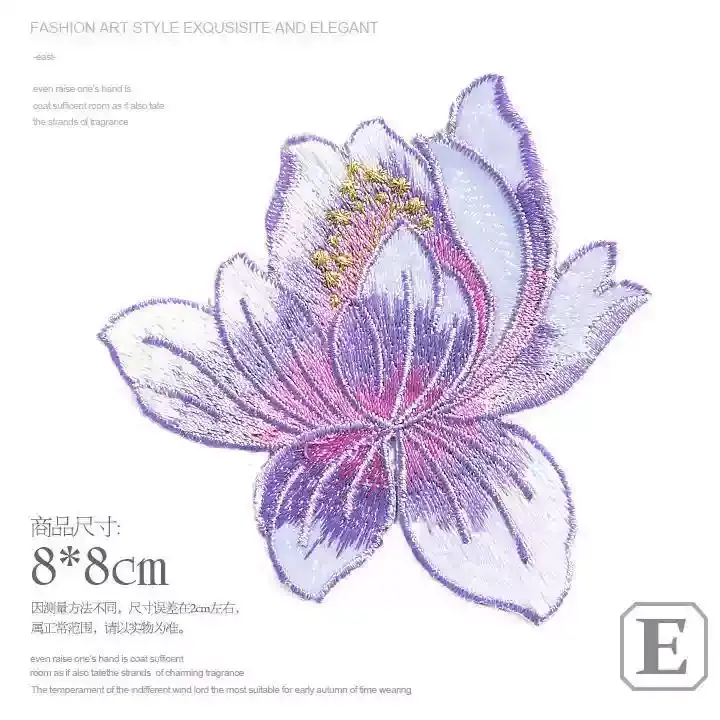

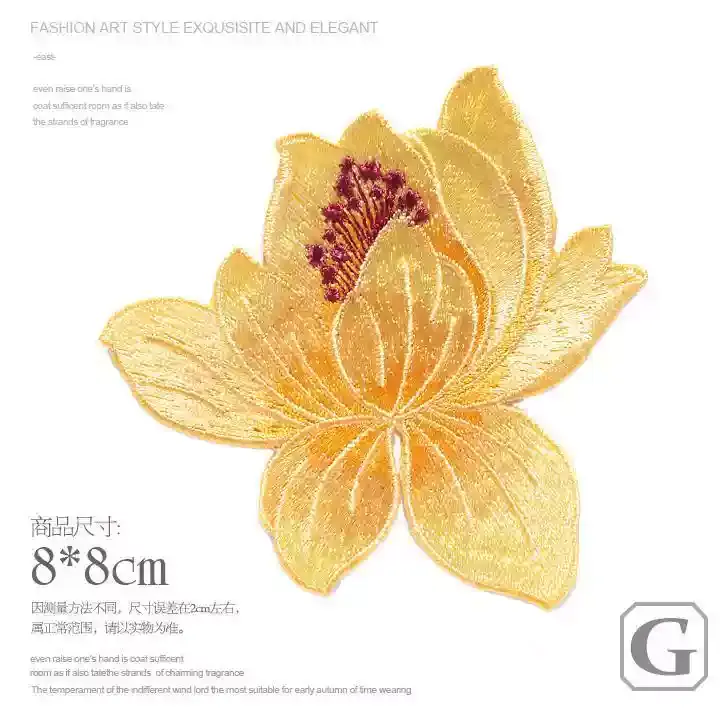

Lifelike pattern effect: Through DTF printing technology, digital images can be converted into patterns that simulate embroidery effects, making the patterns more vivid. This technology can achieve high-precision pattern printing with rich details and bright colors, which can meet consumers’ demand for high-quality embroidery products.

Convenient and fast production methods: Artificial embroidery DTF printing technology can achieve high-speed and efficient production, greatly shortening the production cycle. Compared with traditional embroidery processes, it does not require complex manual operations, reducing labor costs and time costs.

Strong wear resistance: Embroidered garments typically have strong wear resistance and can withstand the test of daily wear and washing. Artificial embroidery DTF printing technology can achieve similar results on a variety of fabrics, providing consumers with more durable clothing products.

Why Choose Imitation Embroidery DTF Printing Solutions?

More flexible

Although traditional embroidery is exquisite, it is often limited by craftsmanship, and there are certain limitations in the speed and breadth of innovation. And DTF printing imitation embroidery opens a new creative door for designers.

It allows designers to boldly experiment with textures, no longer limited to the texture effects that traditional embroidery wires can present. Designers can simulate various delicate, rough, smooth and other textures through digital technology, giving richer tactile and visual layers to the work.

In terms of layering, DTF printing imitation embroidery shows a powerful advantage. Traditional embroidery can require a lot of time and effort in layered design, and due to the limitations of manual operation, it is difficult to achieve complex multi-layer effects. However, with the help of DTF printing technology, designers can easily layered design, superimposing different pattern elements and color layers to create a three-dimensional and deep work.

This layered design not only enhances the artistic appeal of the work, but also provides designers with more room for expression, allowing them to express their creative ideas more freely.

Affordable Alternatives

- The traditional embroidery technique is indeed expensive due to its reliance on a large number of manual sewing or embroidery machine processing. In the traditional embroidery process, not only do skilled embroiderers spend a lot of time on manual production, but also the purchase, maintenance and operation costs of embroidery machines cannot be underestimated. At the same time, the cost of high-quality embroidery threads, fabrics and other materials also increases the cost of traditional embroidery products.

- It does not require expensive traditional embroidery materials. High-grade filaments, special fabrics, etc. used in traditional embroidery can be replaced by more economical materials in simulated embroidery, or similar effects can be simulated through digital technology, thus reducing material costs.

- The production efficiency of the simulation embroidery process is extremely high. The manual production speed of traditional embroidery is relatively slow, while the simulation embroidery can quickly print the designed pattern on the fabric with the help of advanced digital printing technology, which greatly shortens the production cycle. At the same time, high production efficiency also means that more products can be produced in the same time, further reducing the cost of the unit product.

- Simulation embroidery process saves labor. Traditional embroidery requires a large number of embroiderers to perform manual operations, while simulation embroidery mainly relies on digital equipment and technology, reducing dependence on labor. This not only reduces labor costs, but also avoids problems such as unstable quality that may be caused by manual operation.

Affordable Alternatives

- The traditional embroidery technique is indeed expensive due to its reliance on a large number of manual sewing or embroidery machine processing. In the traditional embroidery process, not only do skilled embroiderers spend a lot of time on manual production, but also the purchase, maintenance and operation costs of embroidery machines cannot be underestimated. At the same time, the cost of high-quality embroidery threads, fabrics and other materials also increases the cost of traditional embroidery products.

- It does not require expensive traditional embroidery materials. High-grade filaments, special fabrics, etc. used in traditional embroidery can be replaced by more economical materials in simulated embroidery, or similar effects can be simulated through digital technology, thus reducing material costs.

- The production efficiency of the simulation embroidery process is extremely high. The manual production speed of traditional embroidery is relatively slow, while the simulation embroidery can quickly print the designed pattern on the fabric with the help of advanced digital printing technology, which greatly shortens the production cycle. At the same time, high production efficiency also means that more products can be produced in the same time, further reducing the cost of the unit product.

- Simulation embroidery process saves labor. Traditional embroidery requires a large number of embroiderers to perform manual operations, while simulation embroidery mainly relies on digital equipment and technology, reducing dependence on labor. This not only reduces labor costs, but also avoids problems such as unstable quality that may be caused by manual operation.

Rapid production

DTF printing technology has significant advantages in the rapid production of embroidered garments and products.

First of all, DTF printing technology is able to print patterns onto fabrics and other surfaces at an extremely high speed. Compared with the traditional embroidery production process, it does not require cumbersome manual embroidery or long embroidery machine operations. With advanced printing equipment, patterns can be accurately reproduced on various materials in a short time, greatly improving production efficiency.

Secondly, this artificial embroidery technology enables high-precision pattern printing. DTF printing equipment can accurately reproduce complex pattern details, delicate color changes and clear lines, making the embroidery effect more realistic and exquisite. Whether it is a small and delicate pattern or a large format design, it can be presented with excellent quality.

In addition, DTF printing technology eliminates the lengthy embroidery production process, saving a lot of time and cost for enterprises. Traditional embroidery often requires a lot of manpower and time, and every link from design, plate making to embroidery processing may face delays and quality problems. DTF printing technology can quickly complete the transformation from design to finished product, reducing the uncertainty of intermediate links and improving the controllability of production.

For the fashion industry, fast production means being able to respond faster to market demand and introduce new styles and designs. DTF printing technology allows embroidered garments and products to hit the market in a shorter time, satisfying consumers’ pursuit of fashion and personalization. At the same time, it also provides designers with more creative space and possibilities, allowing them to use their imagination more freely and design unique embroidery works.

Summary of the advantages of DTF digital printing technology

DTF digital printing technology has injected new vitality into the printing and dyeing industry with its advanced technology and innovative concept. It has the characteristics of intelligence, efficiency and greening, providing designers with greater creative freedom and enhancing the brand value of enterprises.

- Intelligent: DTF digital printing technology can be used for pattern design and editing through computer software to achieve accurate color control and pattern typesetting. This allows designers to more easily create complex patterns and designs to meet the needs of different customers.

- Efficiency: Compared with the traditional printing and dyeing process, DTF digital printing technology has higher production efficiency. It can realize fast pattern printing and transfer, greatly shorten the production cycle and improve the capacity of the enterprise.

- Green: DTF digital printing technology uses environmentally friendly inks that do not contain harmful substances and are environmentally friendly. At the same time, it also reduces water consumption and wastewater discharge, meeting the requirements of sustainable development.

Integrated innovation of embroidery and DTF printing

The integrated innovation of embroidery and DTF printing can give full play to the advantages of both, bringing more possibilities to the printing and dyeing industry.

- Personalized customization: By combining embroidery and DTF printing technologies, more personalized customization services can be achieved. Consumers can choose different patterns, colors and fabrics according to their needs and preferences to create unique clothing products.

- Innovative design: The combination of embroidery and DTF printing technology can provide designers with more innovative design ideas. Designers can combine traditional embroidery elements with modern digital images to create clothing products with unique styles.

- Increase product added value: The integrated innovation of embroidery and DTF printing can increase the added value of products. This technology can bring a more refined appearance and high-quality texture to clothing products, making them more competitive in the market.

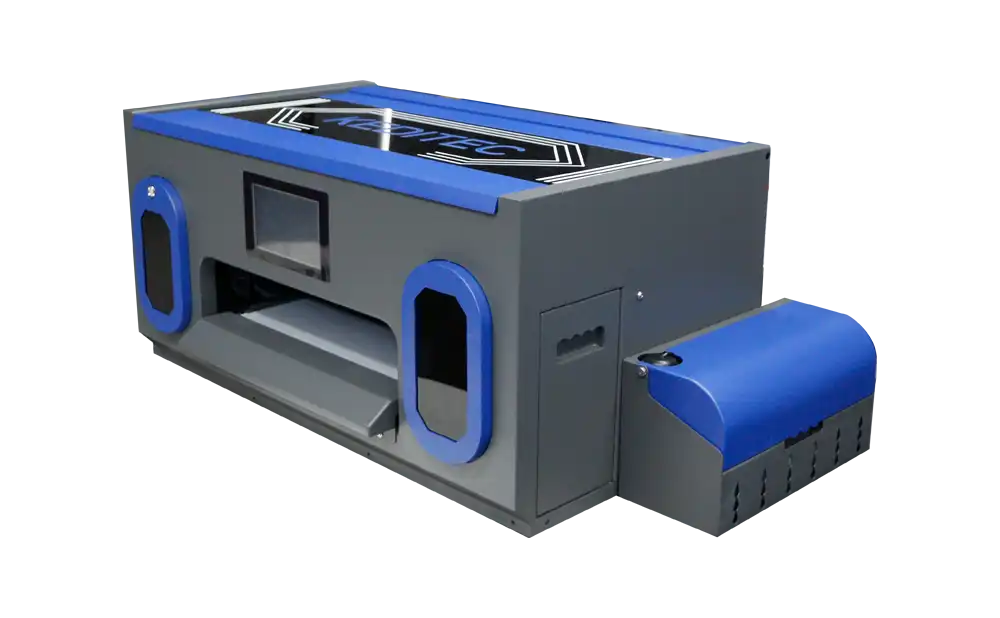

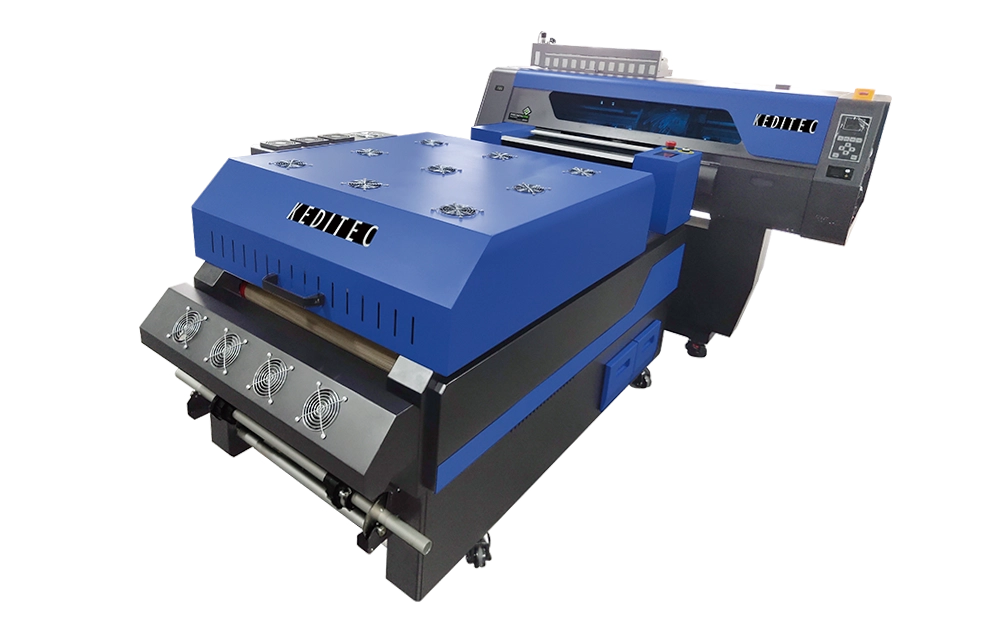

Learn about Keditec printers

DTG printer G1

K450 – 360° inkjet printer

30 pro desktop DTF printer

Keditec 30 DTF printer

Keditec 42 DTF printer

Keditec 60 DTF printer

Contact us