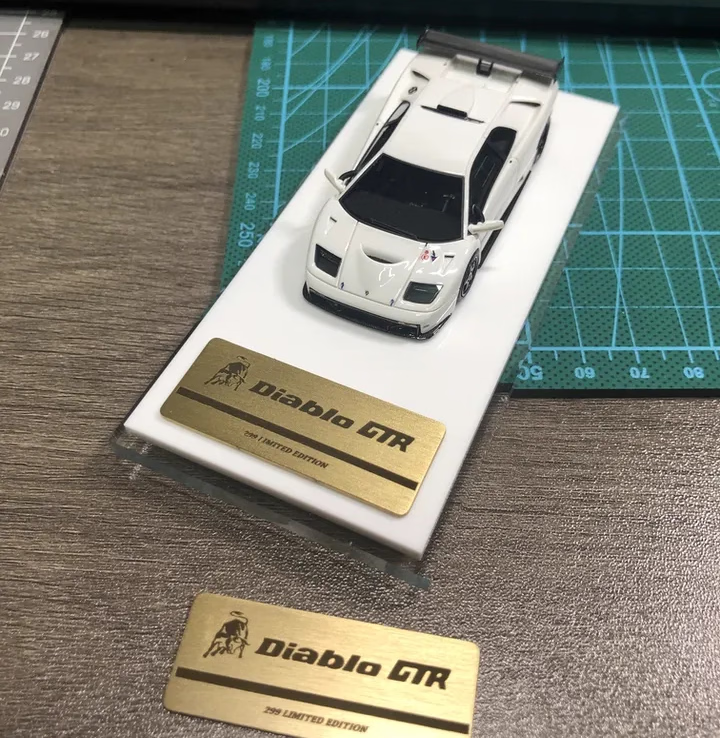

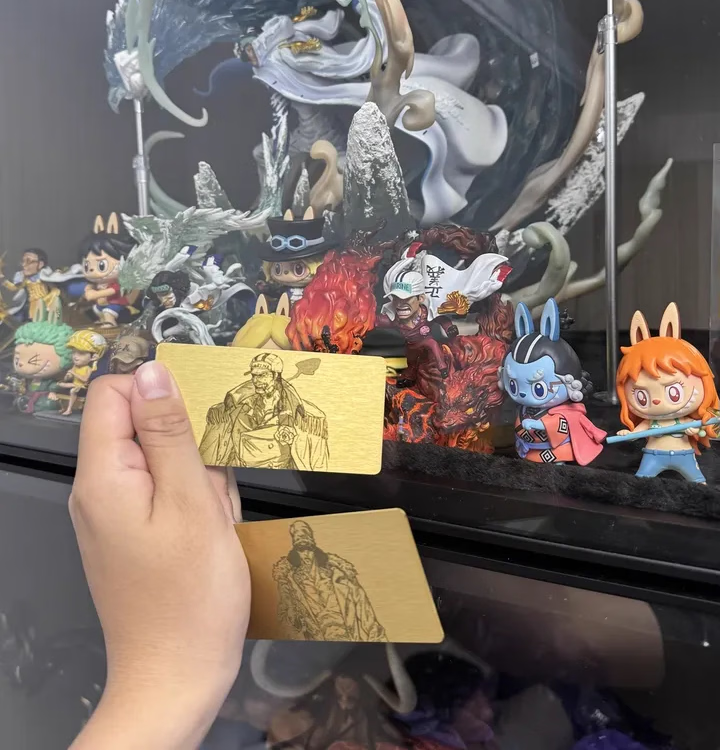

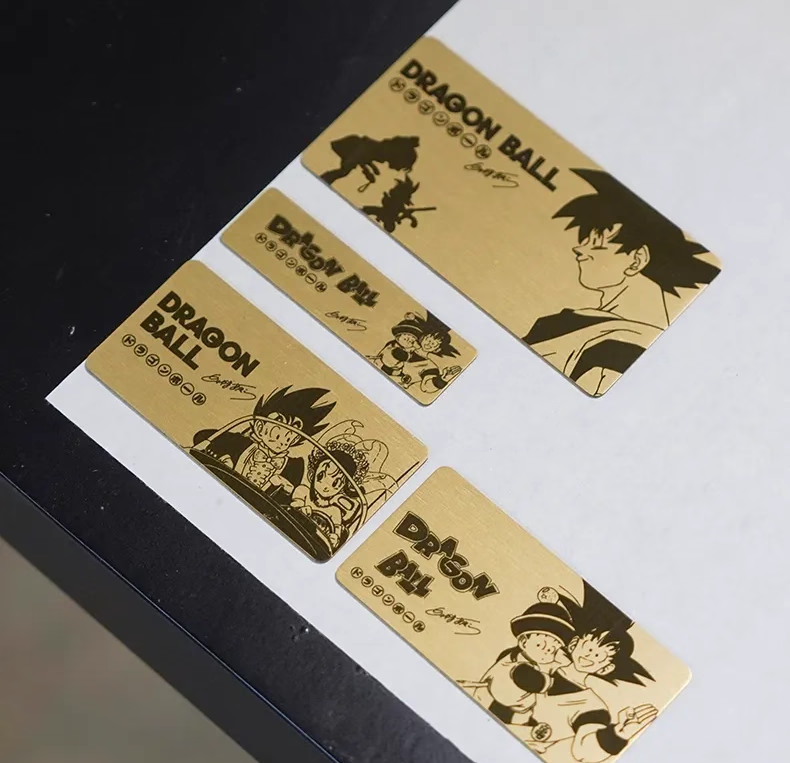

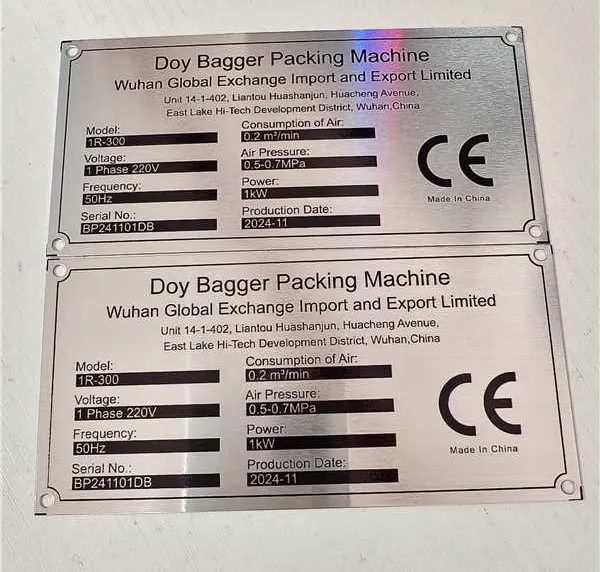

Application of UV Printing on Metal Nameplates

In the fields of modern industry and commerce, stainless steel nameplates are widely used in numerous industries such as machinery, electronics, home appliances, transportation, and public facilities due to their characteristics of durability, corrosion resistance, and ease of cleaning. Traditional nameplate production processes, such as laser printing and etching, once dominated. In recent years, especially with the application of UV flatbed printers, unprecedented changes are being brought to stainless steel nameplates.

I. Laser Printing Etching vs. UV Printing: Principles and Differences

To understand the advantages of UV printing, it is first necessary to grasp the essential differences between it and traditional laser printing etching.

1. Laser Printing Etching on Stainless Steel Plates

• Principle: Laser etching uses a high-energy-density laser beam to scan the surface of stainless steel, causing the surface material to instantly melt, vaporize, or undergo chemical changes, thereby leaving a permanent mark. This process is essentially a processing method that “removes” or “modifies” the material. For stainless steel, laser etching usually forms pits of varying depths (marking) or oxide layers (color-changing marking) on the surface to create patterns or text. If color effects are required, secondary painting after etching is often needed, making the process more complex.

• Characteristics:

o Strong permanence: The mark is directly combined with the material matrix, resistant to wear and corrosion, and not easy to fall off.

o High precision: Suitable for engraving fine lines and text.

o Single color: Usually the natural color of stainless steel (such as silver-white, gray-black) or limited colors obtained through painting, making it difficult to achieve complex colors and gradient effects.

o Material damage: It is a thermal processing process, which may cause a certain heat-affected zone on the stainless steel surface, or even slight deformation.

o Complex process: Color signs require multiple processes, resulting in low efficiency.

2. UV Printing on Stainless Steel Nameplates

• Principle: UV printing, especially the process using UV flatbed printers, is a non-contact printing method based on inkjet technology. Its core principle is to first jet special UV ink onto the stainless steel surface in extremely fine droplets, and then instantly irradiate it with an ultraviolet lamp, causing the photoinitiators in the ink to undergo a cross-linking polymerization reaction, which quickly cures and adheres to the substrate. After curing, the UV ink forms a tough ink film that bonds firmly with the stainless steel surface.

• Characteristics:

o Rich colors: It can achieve full-color printing, including gradient colors, patterns, and photo-level effects, with extremely strong color expression.

o No damage to materials: The light source curing causes no damage to the stainless steel surface.

o Efficient and convenient: One-time printing and forming, no complex post-processing required, with high production efficiency.

o Strong adhesion: High-quality UV ink has excellent adhesion on the stainless steel surface, with good scratch resistance and weather resistance.

o Variable data: It can easily realize the personalized customization of each nameplate’s content.

II. Color Diversity: The Absolute Advantage of UV Printing

In terms of color performance, UV printing has an overwhelming advantage over laser printing and etching, mainly due to its fundamental imaging principles and ink characteristics.

The colors of laser printing and etching mainly depend on the reaction of the stainless steel material itself (such as oxidation to black) or post-painting. The former has monotonous colors, usually limited to changes in metal primary colors such as black, gray, and silver; although the latter can add colors, the painting process is cumbersome, the color choices are limited, and it is difficult to achieve fine color transitions and complex pattern splicing, and the precision of multi-color overprinting is also difficult to guarantee.

However, UV flatbed printers are completely different:

• Multi-color ink system: Modern UV printers are usually equipped with CMYK (cyan, magenta, yellow, black) four-color basic inks. What’s more, some will add LC and LM (light cyan, light magenta) to achieve smoother gradients, as well as white ink (W) and varnish. The addition of white ink makes it possible to print bright colors on transparent or colored stainless steel (such as gold, rose gold, black brushed stainless steel). It can first lay a white base and then print colors to ensure accurate color reproduction.

• True color reproduction: By controlling the jet amount and mixing ratio of different color inks, UV printing can reproduce almost all visible colors with high color saturation and a wide color gamut. Whether it is the spot color of a corporate logo or complex landscape and figure patterns, they can be accurately presented.

• Gradient and layering: The characteristics of inkjet technology enable UV printing to easily achieve delicate color gradients and rich layering, which is difficult for laser etching to match.

• Special effect inks: In addition to basic colors, UV inks also include special effect inks such as gold, silver, and fluorescent colors, which further expand the visual expressiveness of signs.

III. Keditec UV Printer: The Ideal Choice for Special Warning Signs

Among numerous UV printer brands, Keditec UV printers have attracted much attention in stainless steel sign applications due to their excellent performance and good support for special inks. What is particularly worth mentioning is their support for fluorescent inks, providing a perfect solution for metal signs that require special fluorescent warnings.

Fluorescent colors have extremely high visibility and eye-catching properties, and are particularly effective in dimly lit environments or situations requiring warnings (such as safety exit signs, dangerous goods labels, fire equipment tags, traffic warning signs, etc.). Traditional fluorescent signs mostly use screen printing or pasting fluorescent films, which involve complex processes and have limited durability and precision.

Keditec UV printers directly jet fluorescent UV inks onto stainless steel surfaces and cure them, offering the following advantages:

• Vivid colors and strong warning effect: Fluorescent UV inks, after curing, present colors with long-lasting effects, effectively attracting attention and achieving a good warning function.

• Excellent adhesion and weather resistance: They form a strong bond with the stainless steel surface, and their scratch resistance, UV resistance, and weather resistance are far superior to traditional fluorescent films, making them suitable for various harsh indoor and outdoor environments.

• High-precision printing: They can print fine patterns, texts, and barcodes, meeting the needs of complex identification.

• Integrated production: No additional processes are required; it can print synchronously with other colors, making the process efficient and convenient.

This enables Keditec UV printers to demonstrate great application potential and value in the production of fluorescent warning stainless steel signs in fields such as safe production, public safety, and transportation.

IV. Working Principle of UV Printers

UV printers, especially the commonly referred to UV flatbed printers, their working principle can be simply summarized as two core steps: “inkjetting + curing”. The specific process is as follows:

1. Image Processing and RIP: First, professional software (such as RIP software) is used to perform color management, size adjustment, typesetting, and other processing on the image to be printed, and convert it into control signals that the printer can recognize.

2. Placement of Substrate: Place the substrate such as stainless steel sheets flat on the printing platform of the UV flatbed printer. For thinner or uneven materials, vacuum adsorption may be required for fixation.

3. Inkjet Printing: The print head of the printer (usually a piezoelectric nozzle) precisely ejects tiny UV ink droplets onto the designated positions on the stainless steel surface according to the control signals. Modern UV printers usually adopt multiple rows of nozzles, corresponding to inks of different colors, to achieve color printing. The application of white ink makes printing on dark or transparent materials possible, and usually a white base layer is laid before printing colors.

4. Instant Curing (UV Curing): Simultaneously or within a very short time after the ink droplets are jetted onto the surface of the substrate, the ultraviolet lamps (UV LED lamps or mercury lamps) located on both sides or behind the print head emit high-intensity ultraviolet rays. After the photoinitiators in the UV ink absorb the ultraviolet energy, they trigger a rapid photopolymerization and crosslinking reaction of monomers and prepolymers, causing the liquid ink to quickly turn into a solid ink film within a few milliseconds to a few seconds, which firmly adheres to the stainless steel surface. This process is “instant drying upon printing” without the need for waiting.

5. Post-Processing (Optional): In some cases, to improve the wear resistance, gloss, or special hand feel of the ink layer, it may be necessary to apply varnish entirely or partially after printing, or perform simple cleaning treatments.

To sum up, UV printing technology, especially the application of UV flatbed printers in the field of stainless steel signs, is gradually replacing traditional laser printing and etching processes due to its excellent color expression, efficient production capacity, non-damage to materials, and strong personalized customization capabilities. Advanced equipment such as Keditec UV printers, which support special inks like fluorescent colors, has further expanded the application boundaries of stainless steel signs in fields such as special warnings. With the continuous development and maturity of UV printing technology, it is believed that stainless steel signs will have a broader development space in terms of aesthetics, functionality, and diversity in the future, providing better identification solutions for various industries.

Contact us