Canvas sneaker printing

DTF Printing – Custom Canvas Sneaker Printing Solutions

In the continuous development of the printing industry, DTF (Direct-to-Film) digital transfer film technology is like a stunning revolution. This technology allows designers and manufacturers to print stunning patterns directly on PET transfer film, and then transfer these patterns to a variety of textile materials, including canvas sneakers and other types of footwear. Keditec will help you learn more about this process.

DTF heat transfer canvas sneakers

In today’s highly personalised world, keditec has created another extraordinary opportunity for customers to fully appreciate the potential of personalised footwear. This unique way to personalise a wide range of shoes and footwear is through its new direct-to-film transfer process. DTF transfers offer many advantages, eliminating the need for cutting, weeding and pre-treatment.

The successful application of digital DTF printing in footwear manufacturing has opened up new development prospects for the entire printing industry. DTF technology provides unlimited creative space, from personalized canvas shoes to customized clothing, and even home decorations, can be perfectly presented.

Keditec is always committed to bringing customers the latest DTF technology and equipment. We not only provide advanced DTF machines, but also provide comprehensive technical support and services to ensure that every customer can perfectly translate their creativity into reality.

How to achieve fluorescent effect canvas shoes

1. Prepare materials and tools

- Materials include DTF fluorescent heat transfer film, canvas shoes, transfer glue (if the heat transfer film has no adhesive backing).

- Tools include computers and printers (support DTF printing), heat transfer machines, scissors, scraper, etc.

2. Design pattern

- Use graphic design software such as Adobe Photoshop and Illustrator to design fluorescent patterns, considering shoe shape, size, and pattern layout.

- Convert the pattern to a format suitable for the printer.

3. Print and transfer patterns

- Install the DTF fluorescent heat transfer film to the printer correctly.

- Set the print mode and parameters to match the heat transfer film.

- After printing the pattern, dry it naturally or follow the instructions.

Make sure the upper of the canvas shoes is flat and clean. Place the - heat transfer film pattern down on the upper and use a scraper to remove air.

- According to the instructions provided by Keditec, set the heat transfer temperature, time and pressure parameters, start the transfer machine, and tear off the heat transfer film after cooling.

Comparing the advantages and disadvantages of DTG and DTF in the case of canvas shoes

DTF

- Compared with DTG, the colors and patterns are more beautiful and high definition.

- It has waterproof properties.

- The operation is simple, and different DTF membranes can be used to achieve different effects.

- Support fluorescent color applications.

Prices are relatively low.

DTG

- The upper must be unloaded and placed in a flat print or set up with special abrasives.

- If you are not satisfied with the effect of customer customization, you need to disassemble the customer’s shoes.

- The color is relatively inconspicuous and the details are not well realized.

- Incapable of fluorescence.

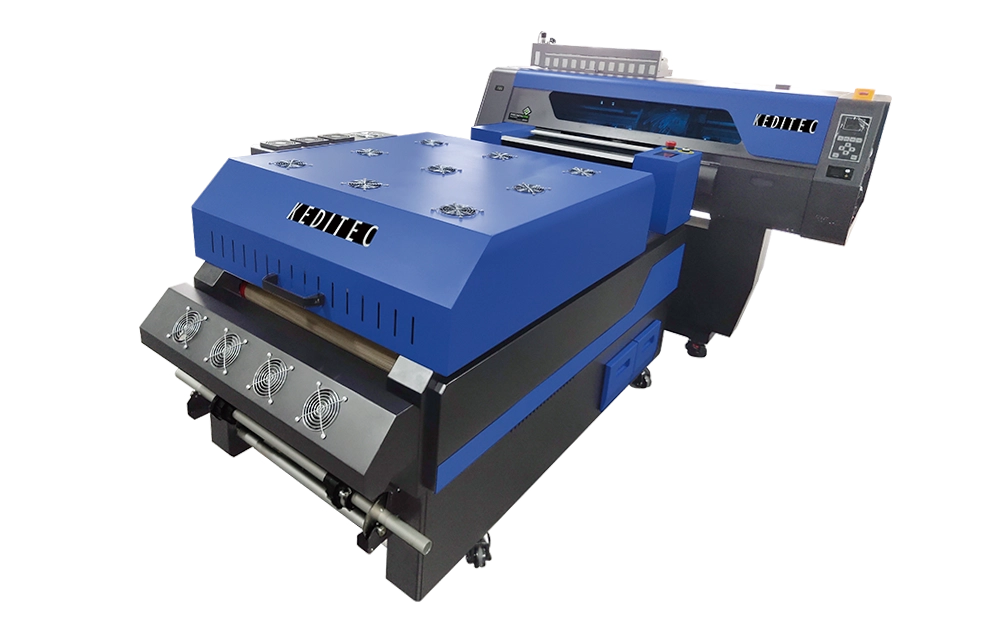

Canvas shoes DTF machine recommendation

When it comes to DTF printing on canvas shoes, choosing the right DTF equipment is essential to bring your design to life and appeal to your audience. By choosing a DTF printer with high-resolution capabilities, you can ensure that every detail of your design is clear and clear, thus enhancing the uniqueness and quality of your work. In addition, it is also important to choose equipment that is compatible with high-quality inks and films so that they are perfectly matched to produce vivid, long-lasting prints. This combination not only enhances the visual appeal of the design, but also ensures its durability.

DTG printer G1

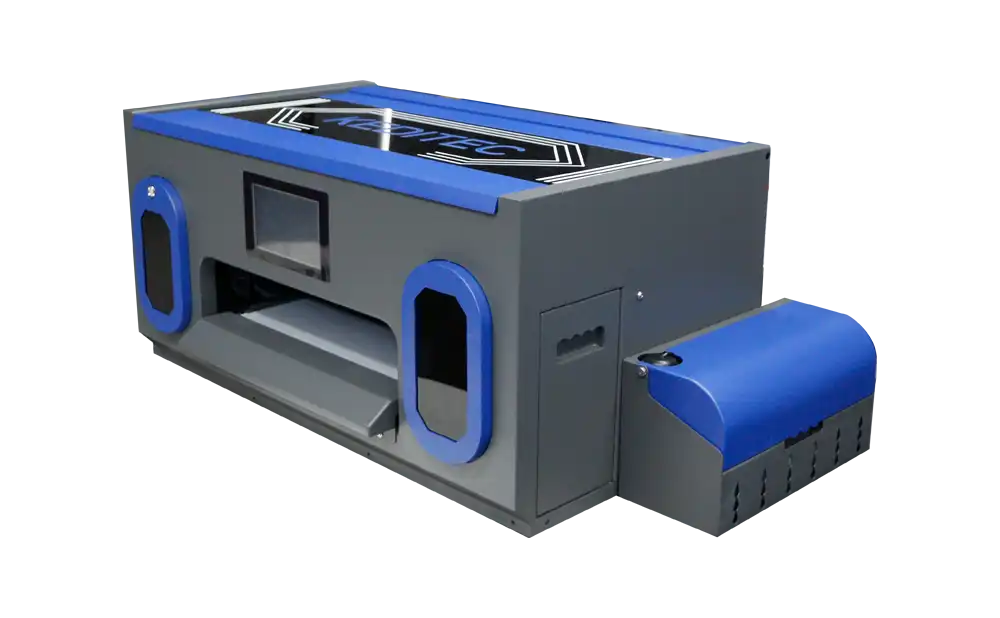

K450 – 360° inkjet printer

30 pro desktop DTF printer

Keditec 30 DTF printer

Keditec 42 DTF printer

Keditec 60 DTF printer

Contact us