Why Incorporate UV DTF?

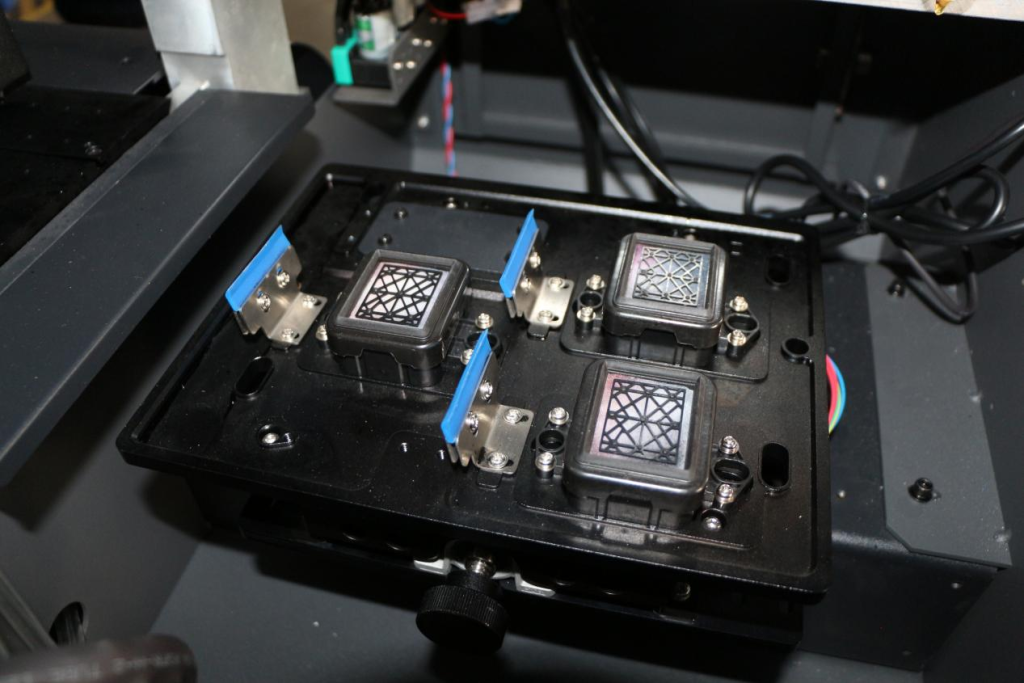

In the realm of printing innovation, UV DTF (Direct-To-Film) has emerged as a game-changer, surpassing the limitations of traditional UV printing. Businesses now have the opportunity to elevate their customization game, thanks to UV DTF printers that produce high-quality, three-dimensional transfers with unmatched versatility. Here’s why your business should consider embracing UV DTF printing:

Mass Production Roll-to-Roll Capacities: UV DTF printers, exemplified by the 24H3R, are designed for mass production, offering roll-to-roll capabilities that enhance efficiency and output.

Ability to Print Variable Data: The speed of UV DTF technology makes it ideal for variable data transfers, enabling the production of barcodes, serial numbers, expiration dates, and other customizable elements.

High-End High-Quality Detailed Designs: UV DTF printing achieves intricate designs and photorealistic images with precision, creating a layered, 3D embossed effect with vibrant colors and crisp edges.

Easy Application Process: The straightforward application process of UV DTF eliminates the need for weeding supplies or a heat press. The Keditec UV K600simplifies the process further with its built-in laminator, making it convenient for various applications.

Aggressive/Durable Adhesive Qualities: UV DTF transfers are renowned for their resilience, boasting aggressive and durable adhesive qualities. They are water-resistant, fade-resistant, scratch-resistant, and wear-resistant.

Versatility In Shape, Size, & Surface: Unlike traditional printing methods, UV DTF printing eliminates constraints related to substrate size, shape, or width. It adheres seamlessly to a wide range of materials, including flexible and rigid surfaces like acrylic, glass, leather, metal, paper, wood, and more.

What Are UV DTF Transfers?

UV DTF transfers leverage UV-curable ink and a robust adhesive backing to create versatile stickers that adhere to almost any surface. Unlike UV printing directly on a substrate, UV DTF printing involves printing on an adhesive medium, resulting in a cured design ready for application.

Mass Produce UV DTF Transfers:

UV DTF printers, such as the 24H3R, boast quick production times, completing a finished product in 2-5 minutes with no limitations on mass production.

Print Variable Data With UV DTF Transfers:

UV DTF technology’s high production speed makes it ideal for printing variable data, enhancing customization options for a range of applications.

Incredible Visual Appeal of UV DTF Transfers:

UV DTF printing delivers stunning visual appeal with detailed designs, vibrant colors, and a glossy finish, ensuring that the applied design stands out.

UV DTF Transfers Have an Easy Application Process:

The Keditec UV K600simplifies the UV DTF application process, offering a user-friendly solution without the need for complex equipment.

Aggressive and Durable Adhesive Qualities of UV DTF Transfers:

UV DTF transfers are built to last, with aggressive adhesive properties that make them resistant to various environmental factors.

Versatility of UV DTF Transfers:

UV DTF printing stands out for its unparalleled versatility, adhering to a diverse range of surfaces and offering limitless possibilities for customization.

Empowering Entrepreneurs with Keditec:

Whether launching a business or expanding an existing one, Keditec offers a comprehensive solution for customization needs. Combined with premium training and support, the Keditec UV K600becomes the tool of choice, empowering entrepreneurs with the knowledge and resources for success.

Discover more about the Keditec UV K600Direct to Film Printer. From starting a business to scaling operations, Keditec provides tailored solutions for every customization endeavor, ensuring entrepreneurs thrive in the dynamic world of printing.